Now, let me start off by asking you a question: are you familiar with Jupiter X, the brand that has been creating a buzz in the industry this season?

It's not Hirahara Kaori's.

It's not FUTU◯E, which can be applied with wax beautifully.

the Jupiter X

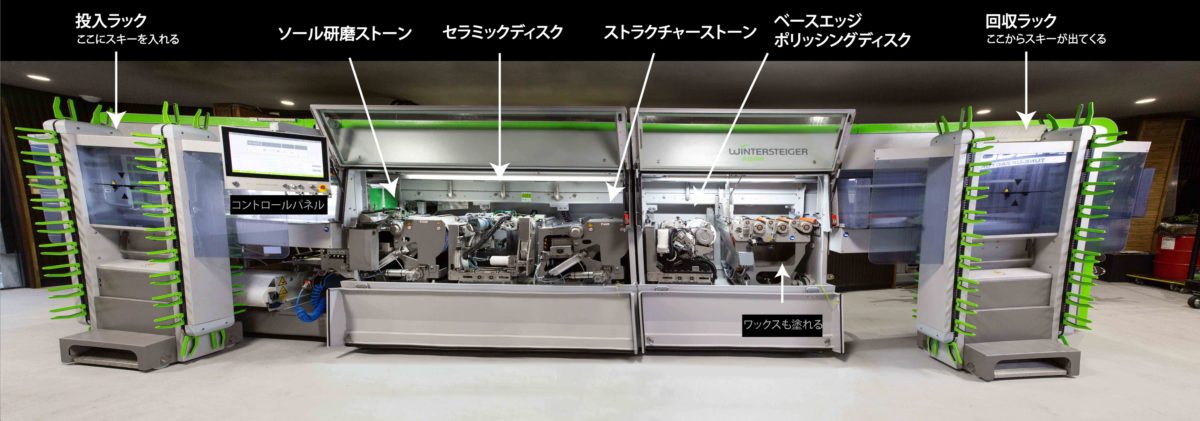

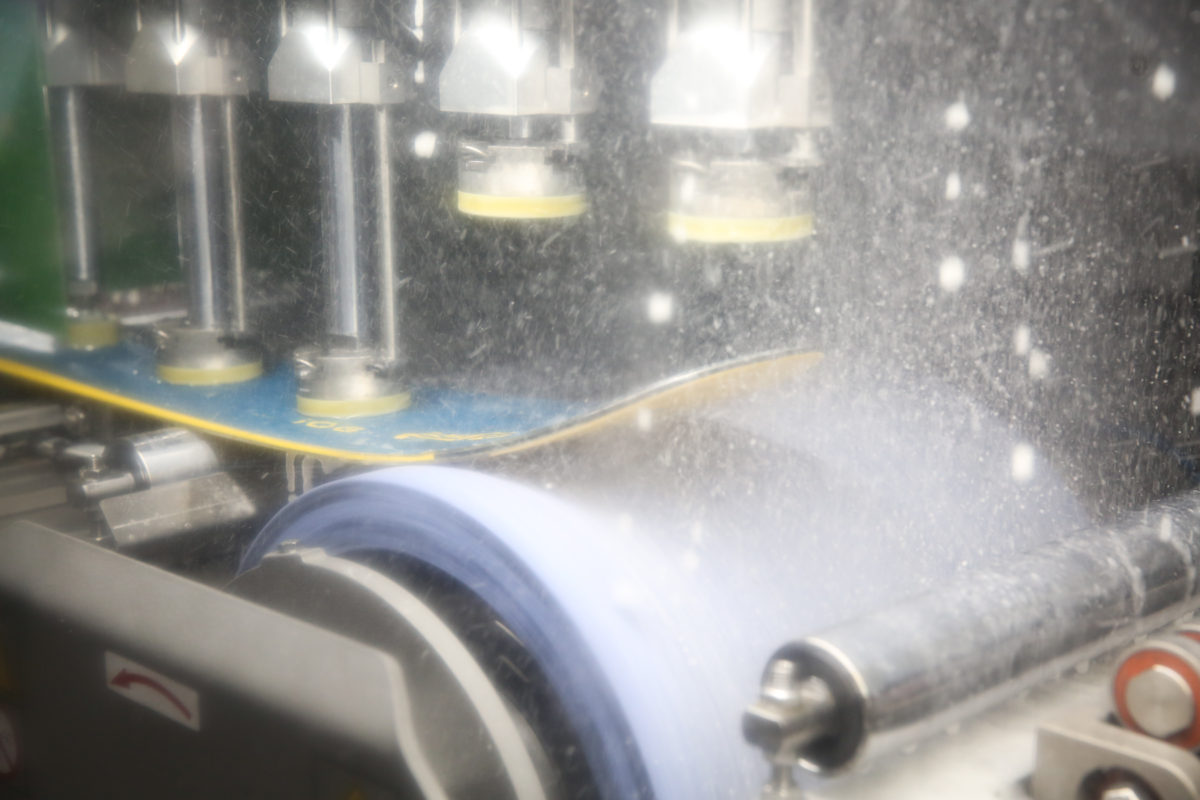

is a fully automatic tuning machine developed by Wintersteiger of Austria the following tuning tasks: fully automatic border cutting

; cleanup of the running surface

; sharpening of the top, center, and tail side and base edges

; adding structure

; polishing the base edge to a mirror finish

; and waxing

.

What's so great about Jupiter X?

Until now, tuning has been thought of as a delicate task that requires manual intervention by a craftsman, but the Jupiter X is an incredible machine that can process up to 70 pairs of skis per hour if the settings are loaded into the machine. If an individual brings in their skis, they can be delivered the same day depending on the condition of the skis and the menu.

Furthermore, the greatest advantage of this machine is that you can specify the edge sharpness, the depth and fineness of the structure, etc., so you can tune them almost freely.

This machine is located at the Zebra Tuning Factory (hereafter referred to as Zebra) inside Creve Sports in Yuzawa, Niigata Prefecture. Zebra, which originally had a thriving rental business, installed the machine to tune up over 30,000 rental skis and snowboards, but it also has great benefits for us ordinary users.

For example, if you're visiting Yuzawa to ski in the winter and the timing is right, you can quickly tune up your ski on the spot and go skiing.

What's even more surprising is that there is only one Jupiter X in the world . There are six "Jupiters" in the world that only sharpen edges or polish the running surface, but Zebra is the only machine that combines all sections and bears the "X" designation .

If we could try out this cutting-edge machine, the only one of its kind in the world, that is causing a stir in the industry, we had no choice but to cover it. Our

editorial team went to try it out to see just how powerful it was.

Actually take it in for a diagnosis

So I called Zebra to request an interview, and they readily agreed. They

"Let's diagnose the skis while actually looking at them,"

so I brought my own skis. They were skis I'd been using for two seasons and had never had a tune-up.

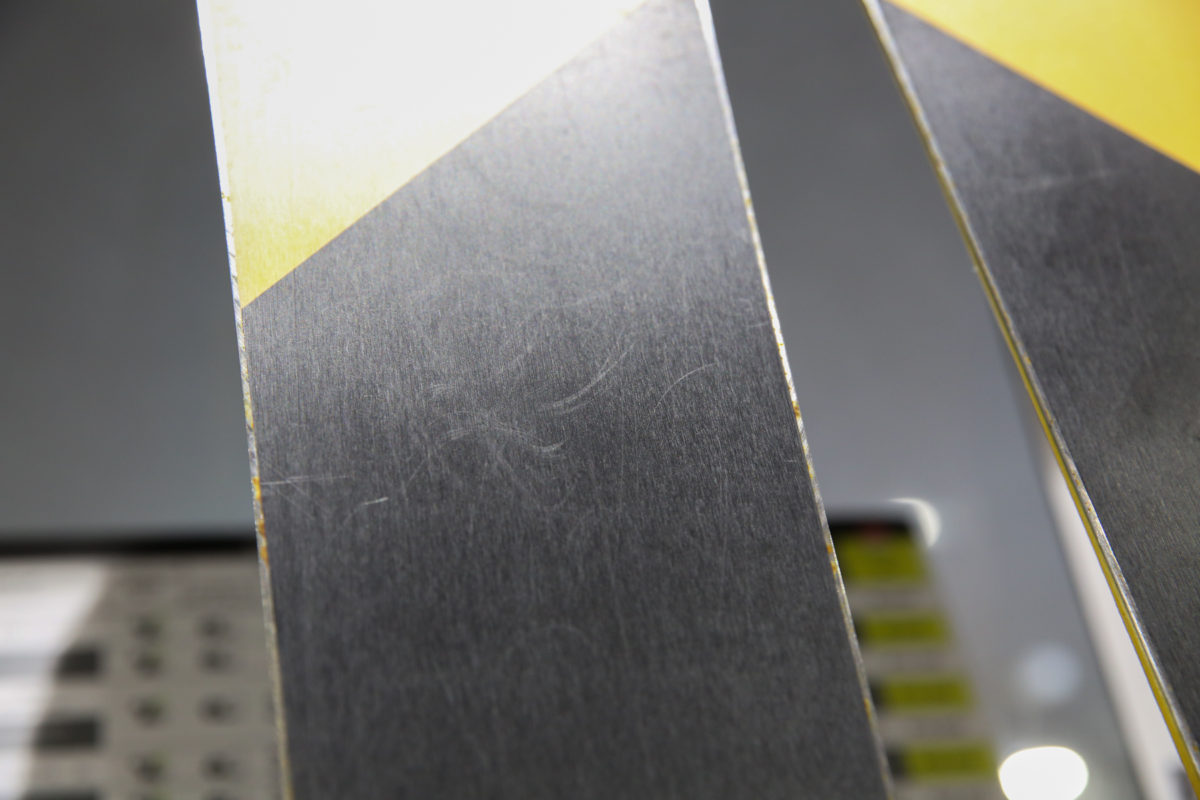

When I took them home and looked at the soles of my skis again, I felt somehow guilty and embarrassed. They were so poorly maintained that it would be no surprise if someone wondered, "Are you really a member of the editorial staff of a ski media company?" There were scratches of all sizes, and the edges were rusty. In fact, since they were on the rails, there were already many intentional scratches on my feet

"Will this really clean it up?"

I asked timidly.

"It will clean up some scratches!"

The person who answered this question so quickly and refreshingly was Mr. Suda, the person in charge at Jupiter

The scratches on the sole from hitting a rail will be removed, but larger scratches like those from stepping on a stone may remain. The point is that the sole is polished to remove the scratches, so polishing too much can affect the durability of the ski itself. If the sole becomes clean but becomes thinner and the ski breaks, it defeats the purpose

Also, the edges of the undercarriage that have become rounded due to the influence of the rails may not be able to be completely rounded. In this case too, if the edges are polished too much and the edges themselves disappear, it will not be a tune-up

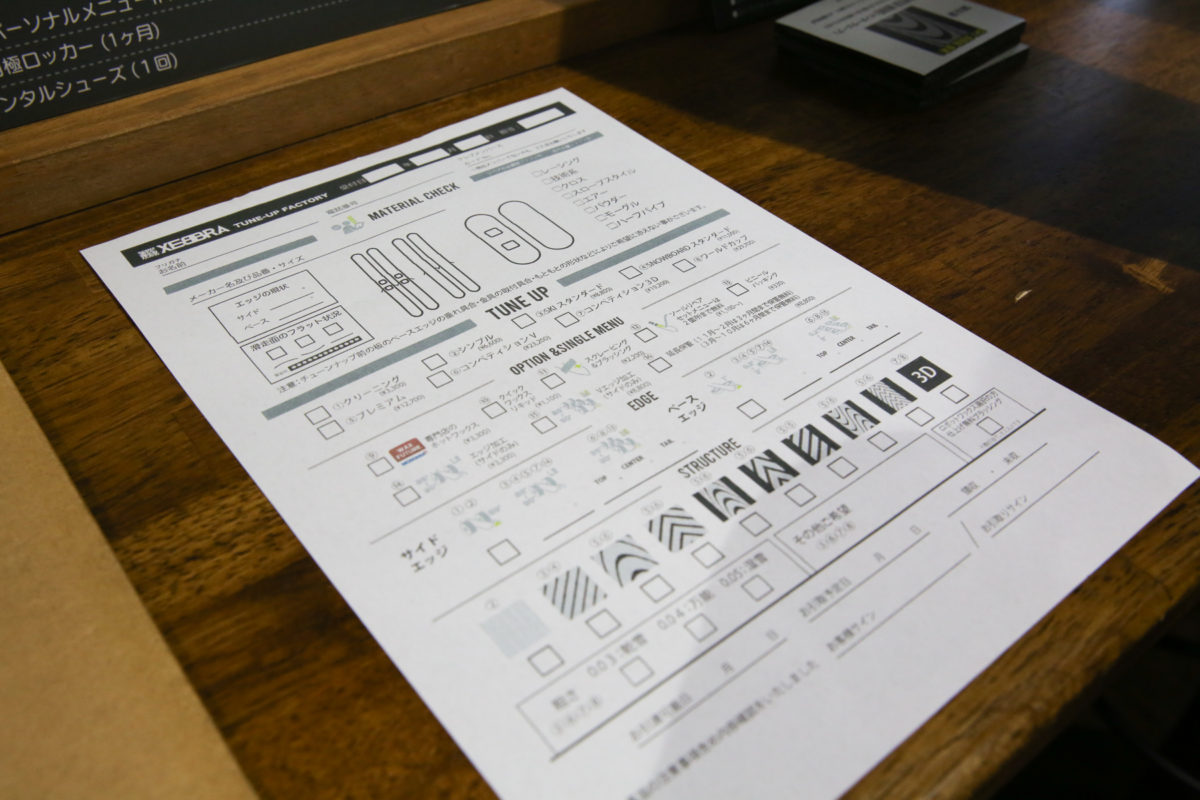

Therefore, before putting it into the Jupiter X, we conduct a thorough material check to determine the extent and type of tuning that is best for the board

The setup is suggested taking into account the individual's preferences, such as the type of place and the way they ski. This diagnosis is very important in finding the ideal board

This time, as a result of the discussion,

First, make the sole flat

- The side edge should be 88.0 degrees and the base edge should be 1.5 degrees

・Introduce structure

This is roughly what I decided to do with the maintenance. This plan includes flattening the sole, polishing and sharpening the edges, and adding structure, and costs 12,700 yen

The skis I brought with me were reborn..

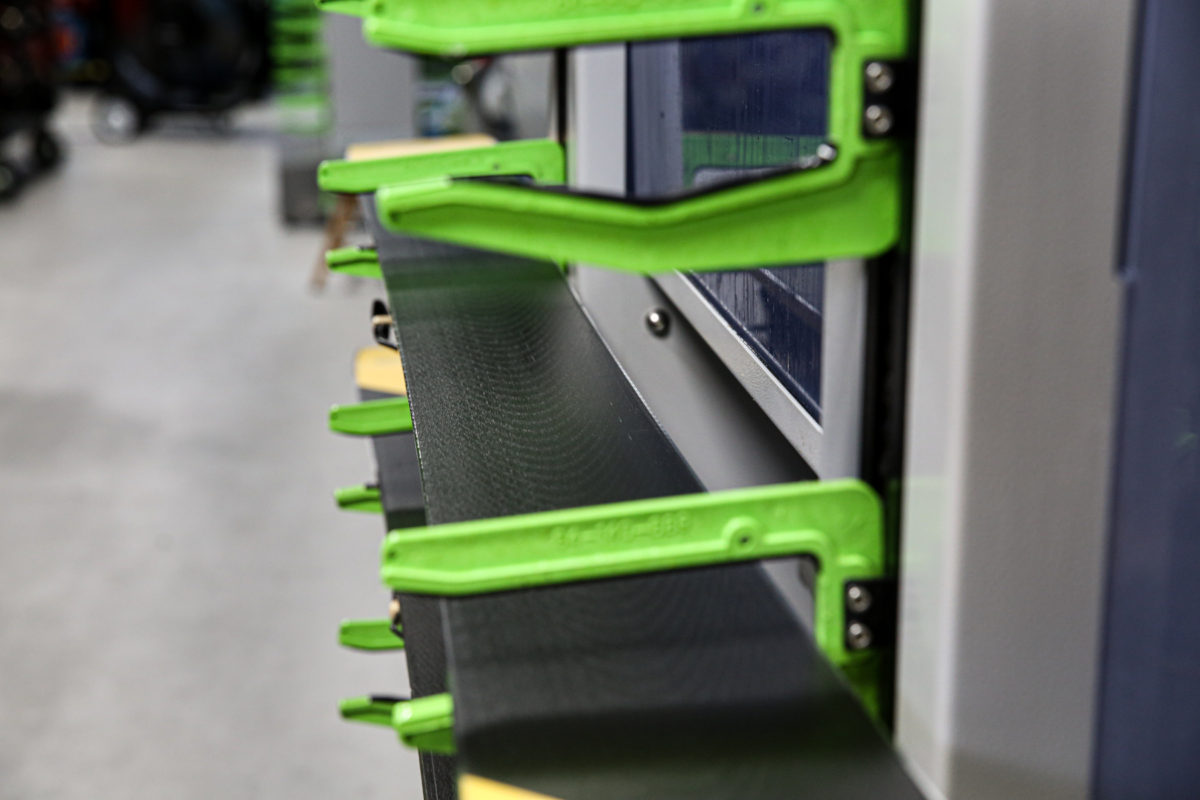

Jupiter is 8.35m long and houses these machines

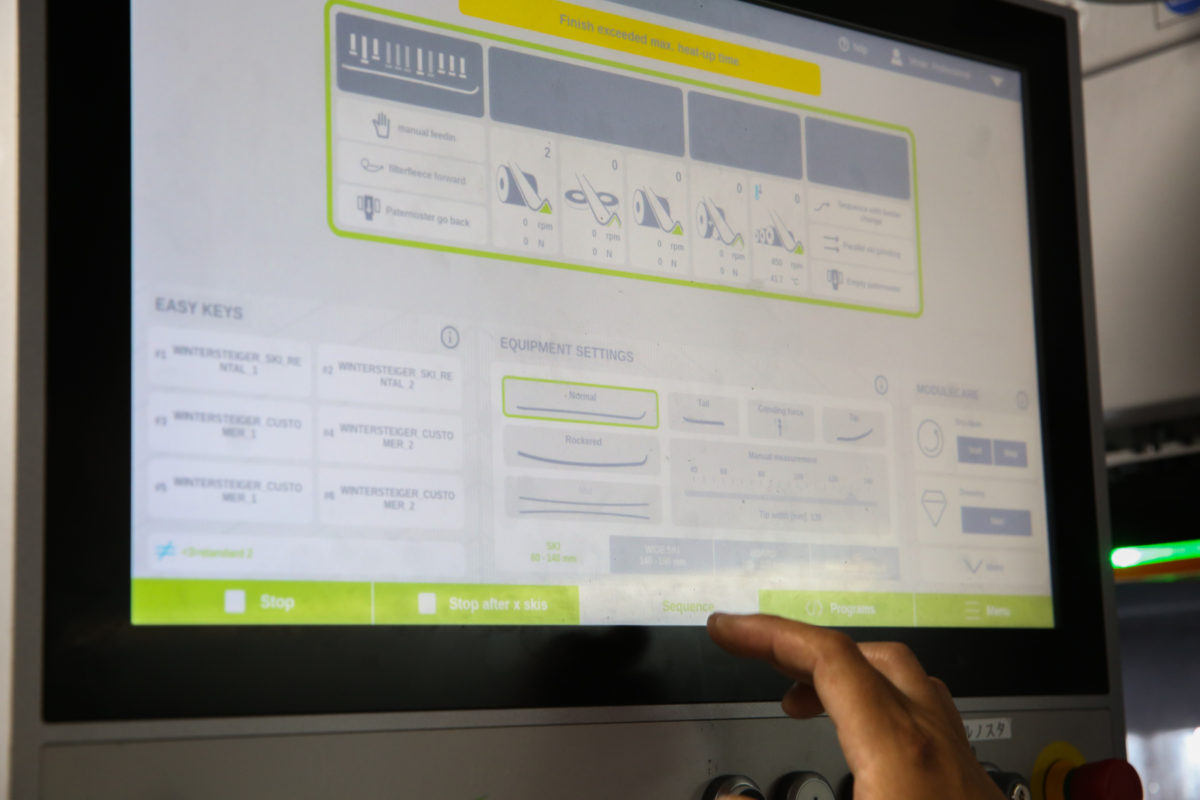

First, you set the type of tuning you want to do from the control panel on the left. You can set the board shape, feed speed, and the rotation speed of the stone that grinds the running surface and edges. You can also set the sequence to fine-tune the grinding not only from the forward direction but also from the reverse. The advantage of the Jupiter X is not only its speed, but also its accuracy. You can insert the board straight and tune it with a consistent pressure and speed

First, polish just the sole and see how it goes

With the Jupiter X, all processes can be done at once, but since the tuning methods for general users' boards vary, the soles are polished and the edges are sharpened, and the finished product is checked each time

The work was completed in no time, and even after polishing the sole once, many small scratches were removed, leaving the shoes looking very clean

Next, I rounded the edges. I set the angle so that the whole thing was 1.5 degrees, and put it through the machine. I wondered what would happen to the rust on the edges that was there in places

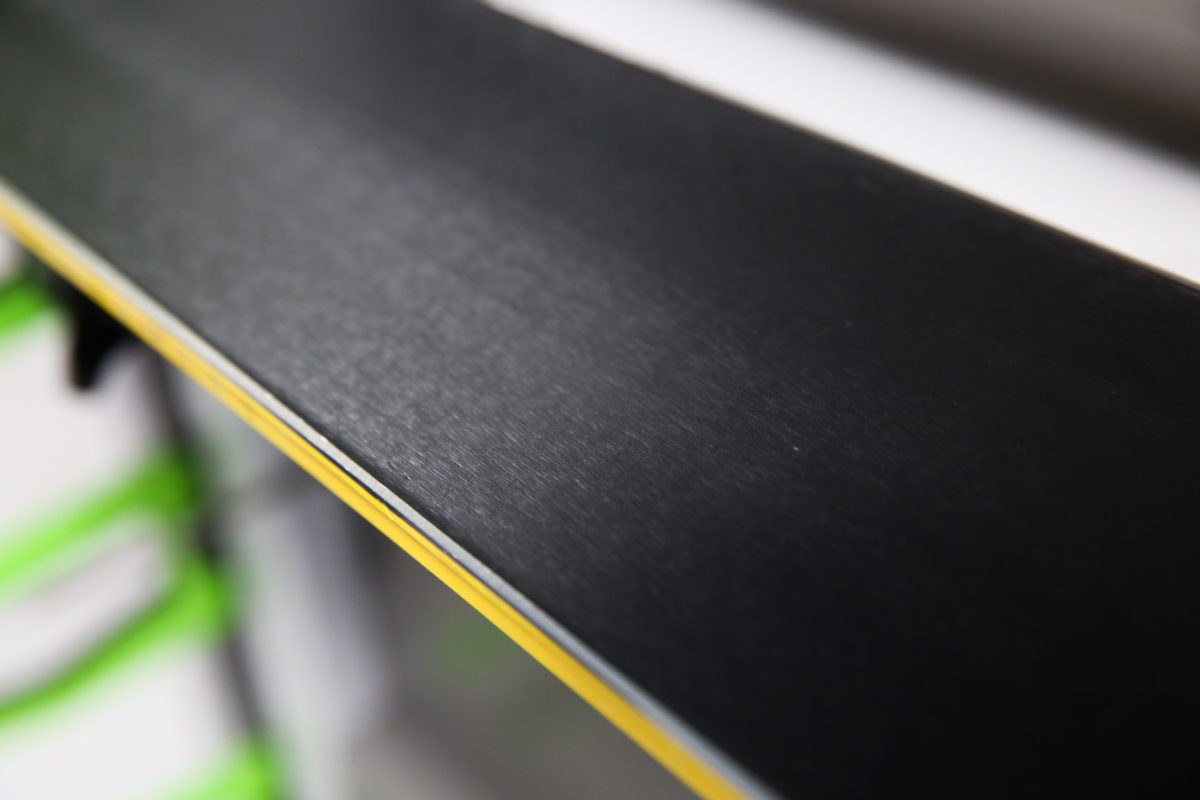

And what came out was..

The skis came out with beautifully designed edges that were so different they were unrecognizable. They looked so different I wondered, "Are these really my skis?"

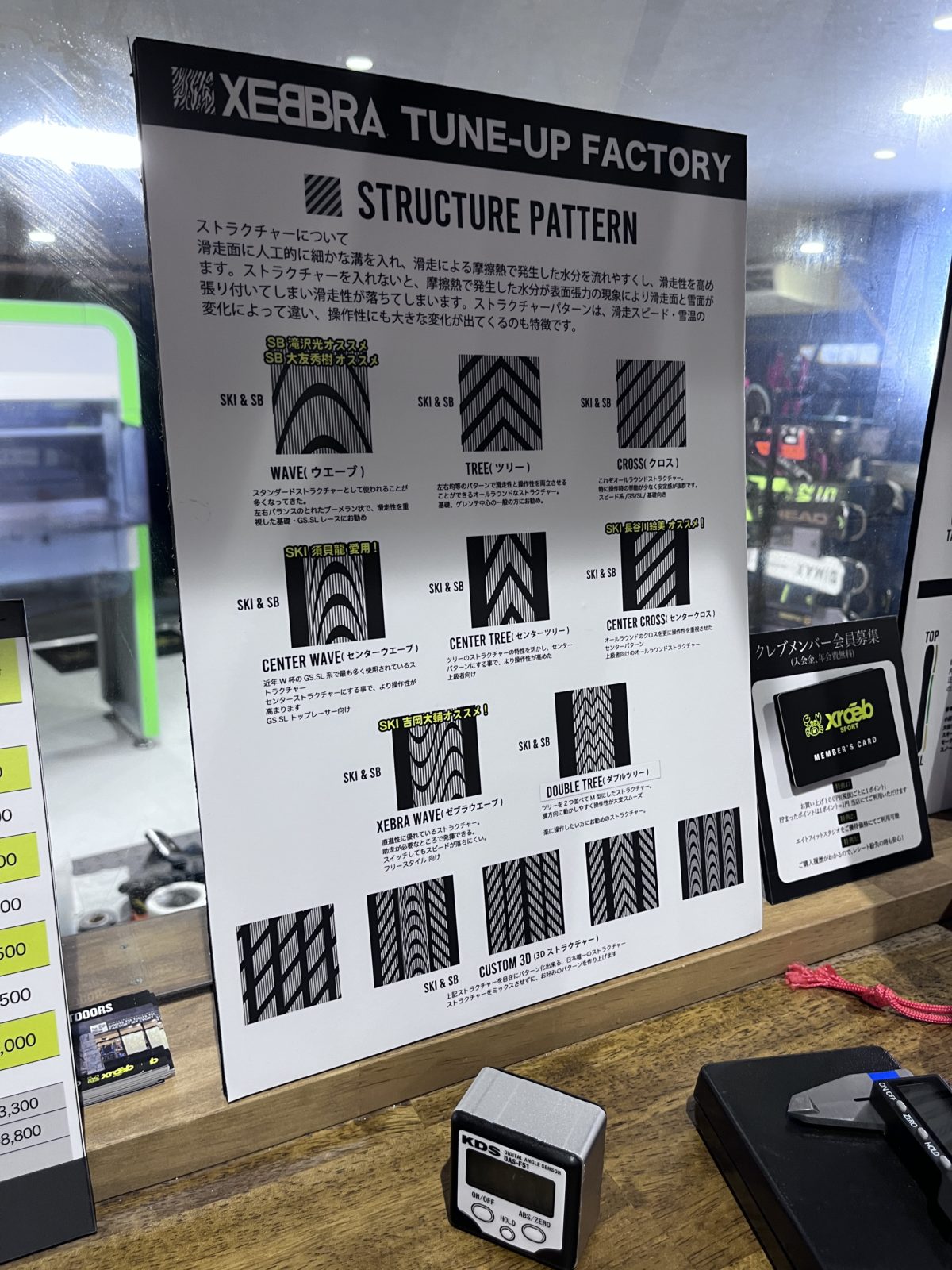

Next, structure is added. This structure is the process of artificially creating fine grooves in the sole. This makes it easier for water generated by frictional heat while sliding to flow away. Without structure, water would pool between the sole and the snow surface like surface tension, reducing the ski's ability to glide

The structure is so important to ski performance that each ski manufacturer has their own confidential structure pattern

The strength of Jupiter is that you can insert these structures almost freely by changing the settings. Furthermore, a function that will be upgraded in the future is "3D structure." Not only will it be possible to insert structures of any pattern, but it will also be possible to adjust the depth for each part, whereas normally you can only finish to a certain depth

This time, I took the opportunity to try the CENTER WAVE pattern recommended by Ryo Sugai, who also competed in the ski cross at the recent Beijing Olympics. This revolutionary structure combines maneuverability and gliding performance by providing a groove in the center that allows water to flow easily and leaving the sides near the edges free of structure

Load the structure settings in the control panel and set the depth. You can choose shallow, medium, or deep. This time, I set it to medium depth. This is what came out

It's a little hard to see in the photo, but the pattern is clearly visible to the naked eye

Finally, the base edge is polished with a finishing disc.

This removes any minor scratches on the base edge caused by the stone disc and gives it a mirror finish. Please watch the video to see how this works.

The faint polishing marks that had previously been visible have now completely disappeared, leaving the surface smooth

The finished board had almost all the scratches on the running surface and the structure was beautifully formed. The rust on the edges that had been sticking out in places had completely disappeared, and even the faintest scratches had been removed with the polishing disc. Some of the areas that had been in contact with the rails underfoot were rounded, but if I sanded them down any further the edge itself would disappear, so that's unavoidable

It took just under an hour from diagnosis to completion of the work. Since I was doing interviews while I was there, the work itself probably finished a little faster. Depending on the ski, if the sole or edge is damaged, further polishing work will be required, but the ski I brought this time was one that I had been riding in the trees and in the park all season without paying any attention to, so I think it had a lot of scratches

This time, the plan was to round off the edges, polish the soles, and add structure, all for 12,700 yen, but I'm personally very happy because my favorite board has been reborn and is back in my hands. For

now, with this board now perfectly structured, I'm even more excited to ski this season.

You can also view the Jupiter X through the glass inside the Kreb store. If you're interested, be sure to stop by the Zebra Tuning Factory inside the Kreb store when you visit Yuzawa Town this winter to ski

If you would like to see a video of Jupiter in action, please check out the manufacturer's YouTube channel

Clev Sports

Kandatsu, Yuzawa-cho, Minamiuonuma-gun, Niigata Prefecture,

949-6102 025-788-1788

Interview and writing: Daigo Onozuka