A must-have glove for skiing and snowboarding. Although it doesn't have as much presence as hard gear such as boards and boots, it is actually very important. If your hands are cold, the fun will be halved. Those who haven't paid much attention to choosing and handling gloves so far may have lost a little in the fun snowy mountains. In the 2023-24 season, let's deepen our understanding of gloves so that we can enjoy skiing more comfortably and make the most of our time on snowy mountains.

Why wear gloves in the first place?

Why do you wear gloves when skiing/snowboarding? That's exactly why.

1.

Keep hands warm 2. hand protection

Of course, keeping your hands warm is to protect your hands from the cold in the snowy mountains.

If your hands get too cold, you won't be able to move your fingers, which can make it difficult to handle poles, buckle boots, zippers, wear goggles, etc. In extreme conditions, you can even get frostbite. I want it to be warm enough so that my hands can move smoothly. And in the snowy mountains, there are situations where various hands can get hurt. Sliding in a tree and hitting a tree, falling over on a snowboard and rubbing your hands with coarse snow, cutting your hands when you put on and take off your bindings, etc. You need to protect your hands from injury.

Elements required for a snow globe

In order to keep the hands warm and protect them on snowy mountains, gloves must have the following elements. In order to protect your hands, it is necessary to be strong against external impacts, that is, the surface material must be durable. And in order to keep your hands from getting cold, the structure of the glove is designed to keep you warm, the batting itself has high heat retention, and it contains a water-resistant material that prevents wet water from penetrating from the outside. It is preferable to be

And don't forget about "ease of movement". The cutting and sewing of the parts of the glove is a big point in whether it is easy to move the fingers as desired. Depending on how the parts are combined, the texture may become rough and hard, making it difficult to move the fingers.

how to make a glove

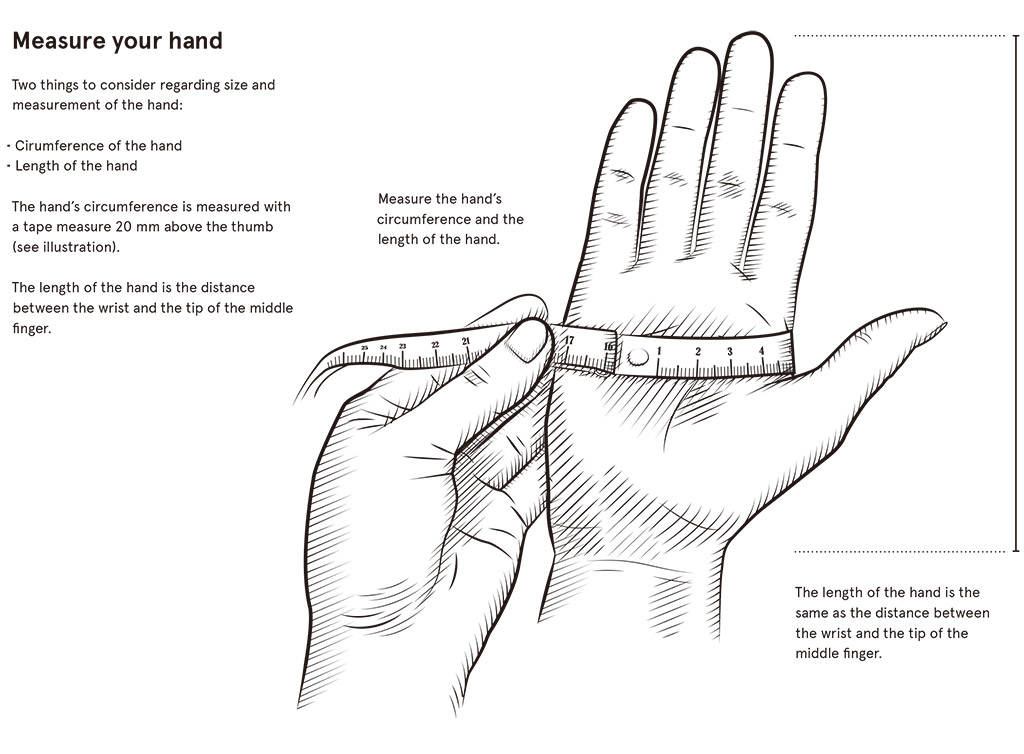

The process of making gloves begins with the process of first measuring the size of the hand.

Here's how HESTRA measures your hand. Measure the width of your palm. In Sweden, the country of origin of HESTRA, and in European countries, glove size is measured by width, but in Japanese companies that manufacture motorcycle gloves, etc., it is standard to measure from the top of the middle finger to the wrist. The difference between the vertical culture of Japan in terms of language and human relationships and the horizontal culture of the West may be reflected in unexpected ways.

The origin of the glove

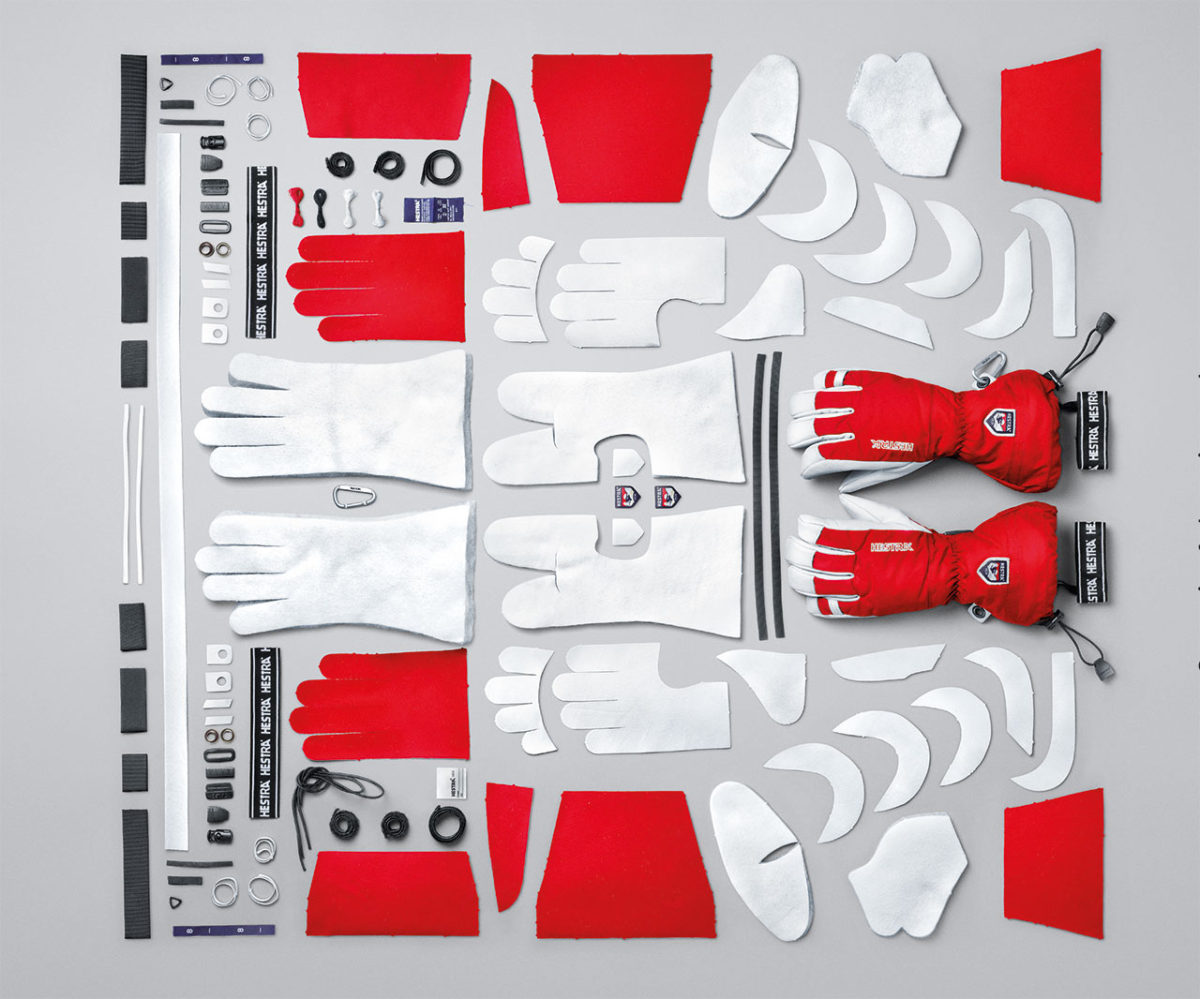

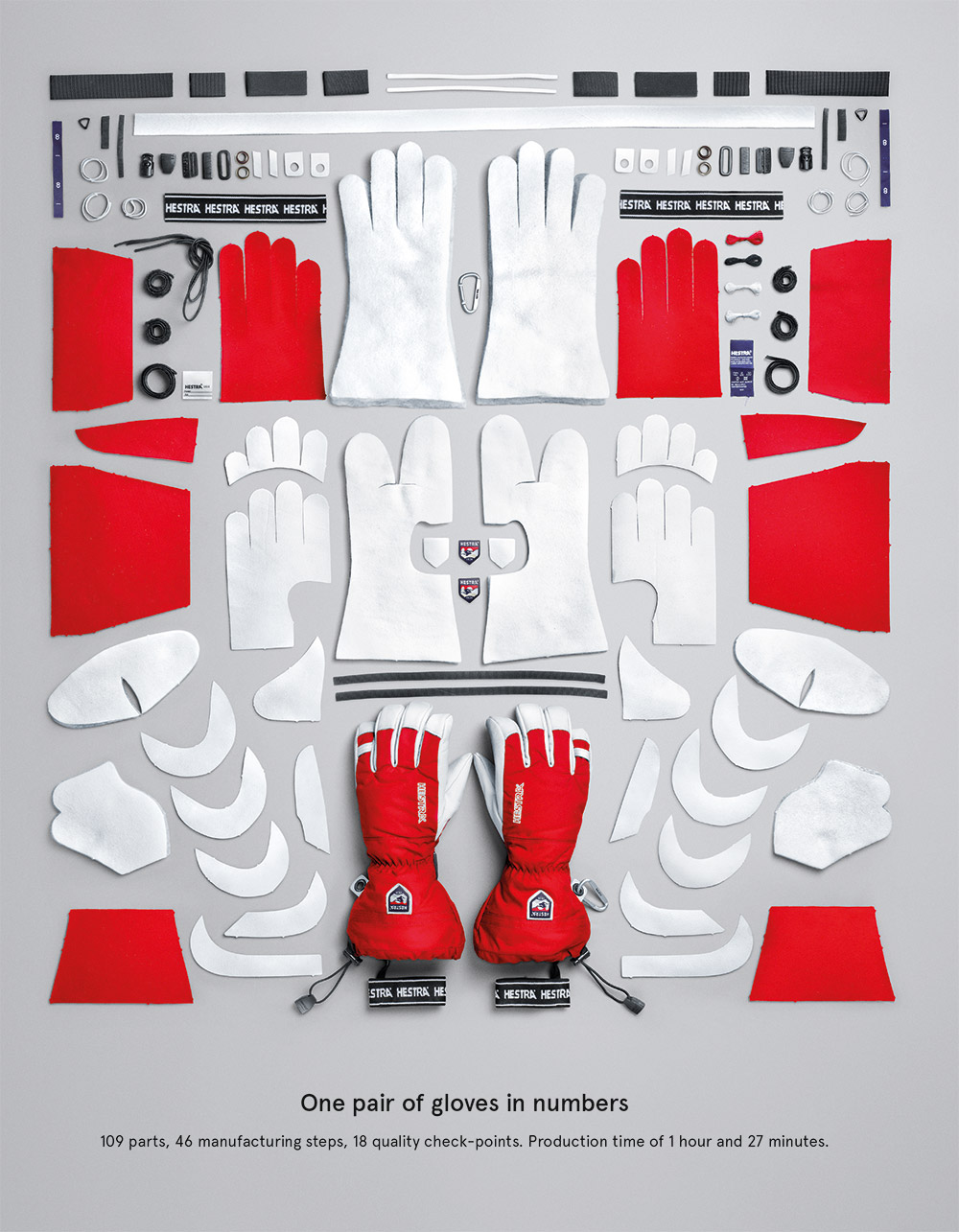

109 parts, 46 processes, and 18 inspections are required to make a pair of gloves!

This is the "component of the glove". In the case of HESTRA gloves, one pair actually consists of so many parts. The number is 109! The process of stitching together fabric materials and attaching small parts requires 46 actions. In addition, it has to pass 18 quality checks. It takes 1 hour and 27 minutes to complete one glove. How laborious!

Grove structure

When the disassembled parts of the glove above become the glove, the so-called glove structure is like this.

(Figure below) From the outside, the shell (outer material), membrane (waterproof film), lining (filling), and lining are the most common four-layer structure. There are three-layer gloves without a membrane, and thin gloves without lining.

■ 4-layer structure is the most common

Lining (batting)

The concept of keeping warmth is the same as layering clothes. The thickness and material of the lining (filling) of gloves is adjusted in the same way that you can adjust the warmth by wearing a down mid layer or cotton like a sweatshirt. There is also a type of glove that the lining can be taken out like the photo below the lining.

There are also fleece materials made from polyester and wool that is used for the filling. The strength of wool is that it maintains heat retention even when it contains some moisture. Even if snow gets inside the glove and it gets a little wet, it doesn't get cold.

shell (outer material)

The materials used for the shell of the glove, the so-called outer material, can be roughly divided into two types: nylon and leather. Nylon has various materials with different thicknesses and properties, and the advantages of nylon include waterproofness, windproofness, water resistance, moisture permeability, durability, and lightness. Polyester and synthetic rubber materials are also used.

The advantage of leather is overwhelming durability and softness. The leather becomes softer and more supple the more you use it, and it adapts to the movements of your hand. There are also leathers with excellent moisture permeability. Once you use it, you will feel its comfort. HESTRA, which has become an icon of leather snow gloves, has been making gloves using leather consistently since its founding in 1936, but the background is the high functionality unique to natural materials and the tasteful texture that is in harmony with nature. However, it continues to attract users.

■ Types of animal leather

Our daily lives are full of leather products. Leather shoes, leather bags and wallets, leather jackets, leather sofas, and more. There are actually various types of leather, and each animal skin has its own characteristics.

Cows, sheep, goats, horses, and crocodiles are popular and easy to imagine, but there are also buffaloes, deer, pigs, and wild boars. Water buffalo leather is used for high-grade leather jackets, chamois leather used for cleaning eyeglasses is oil-tanned deerskin, and cordovan horse leather has a beautiful luster, elegance, and durability. The world of leather is really interesting when I hear that boar leather, which is said to be the world's finest, is expensive and difficult to obtain.

■ Goats and cows are the main ingredients in snow globes, and deer are also included.

Goat leather and cowhide are the main materials used in snow gloves due to their flexibility and water resistance.

Deerskin is partly added there. Goat leather is strong, durable, and has a unique texture (three-dimensional wrinkle pattern on the surface of the leather), so you can enjoy the change over time. Children's goat leather (kidskin) is softer and more beautiful than adult leather (goatskin), and is used for shoes and gloves. Cowhide is a material with a wide variety of surface treatments, so as you know, it is used for all kinds of leather products such as bags, shoes, and gloves. Goat Army Leather in HESTRA is the highest grade goat leather, the most durable, waterproof, and has excellent moisture permeability. Originally used to make military gloves. Cowhide leather resistant and highly breathable, making it a great match for gloves.

In addition, deerskin is an excellent material for gloves because it stretches and recovers. Elkskin is made from elk raised in Sweden and Finland, and Deerskin is made from North American white-tailed deer. Both leathers are surprisingly soft and retain heat. Doesn't it feel like once you've learned a little bit about leather like this, you'll develop a different attachment to gloves than ever before?

Membrane (waterproof film)

There are various materials for the membrane that functions to keep the snow glove dry, but the most well-known is probably GORE-TEX® A waterproof and breathable material that has the same function as human skin, releasing heat and moisture inside the glove to the outside. It keeps water out and keeps your hands dry and comfortable in the snow. It also keeps your hands warm and comfortable by shutting out the wind.

On the other hand, it is undeniable that the GORE-TEX® makes it stiffer and reduces the fit. It is seldom used for work-type gloves to move fingers well. By the way, HESTRA also uses

waterproof and breathable material CZone® " There is also the advantage that it is possible to cut suitable for gloves without impairing the fit. In this way, the membrane is adopted according to needs.

glove design

Most of the designs of snow globes are designed for functionality rather than aesthetics, as they are used under the harsh natural conditions of snow. What kind of design should be in order to be functional? In addition to the materials and structure, there is a design ingenuity that comes from the need to cover the hands and move the fingers.

shape

It is unexpectedly stressful to open and close the zipper of the wear with cold and numb hands in the snowy mountains. Whether it's gripping poles, adjusting bindings, or wearing goggles, it's better to be able to move your fingers even a little. The shape of the glove directly affects the movement of the hand.

■ Five fingers, three fingers, mittens

Snow globes are divided into these three types.

| merit | Task | |

| 5 finger gloves | Good fit and fine finger movement | Fingertips tend to get cold, hard to dry, and tend to get stiff (depending on the material) |

| 3 finger gloves | The thumb and index finger are independent, so they are necessary and sufficient for grabbing things.The part that is gathered is warm. | There are large individual differences in how the fit feels.・It is necessary to get used to how to move the three. |

| mittens gloves | The fingers are gathered together to keep you warm. The pole is relatively easy to grip. | Poor fit, unable to perform fine movements, jumping and grab tricks are quite difficult |

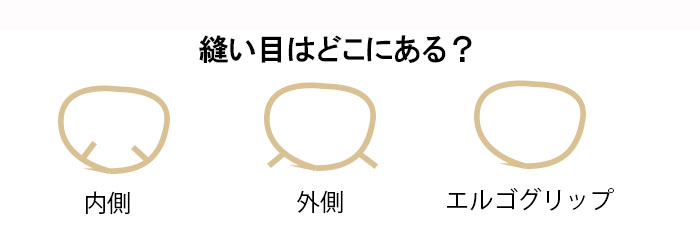

■ Ergo grip

In terms of design, HESTRA also uses a technology called "ErgoGrip", which is ergonomically designed to fit the fingers in the most relaxed and natural state. is. Developed by Matsuoka Gloves, a Japanese glove maker famous for its motorcycle and golf gloves, in 2009 it won the "Technology Award", the grand prize in the processing technology category, at the world competition for leather materials and processing technology. It also holds a patent.

ErgoGrip researches the curves and movements in millimeters in order to obtain the natural shape of the human hand, realizing a high-dimensional fit, cutting and sewing parts that follow the shape and movement of the fingers, making the fingers comfortable. Less energy loss during movement. By matching the shape of the hand, wrinkles and wrinkles are less likely to occur on the surface, making it easy and comfortable to grip the pole. There is no stress because the fingertips are easy to move when handling tools. It means that you won't get tired even if you wear it for a long time in the snowy mountains.

Sewing

Gloves are made up of various parts, and how they are sewn together also affects the fit and comfort. In particular, if the fingertips touch the seams when performing delicate movements, it may feel uncomfortable or make it difficult to perform accurate movements. Sewing is also an important point that is directly linked to the ease of movement of the fingers and the feeling of use.

Functional seams

The joints on the flat side of the fingers are cut into individual parts, and the seams of the joints are designed to fit between the fingers. Three-dimensional stitching with bent fingers provides a good fit and a smooth feel.

Ingenuity in how to use gloves

There are various ways to use gloves depending on the user.

There are types such as mittens for heat retention, 5 fingers for ease of movement, and 3 fingers for the best of them, but recently, even more interesting types have appeared. Here is the representative. SWANY's "Bocco" for free riding has a thin inner glove inside a leather mitten like this. Function.

Warm and waterproof genuine leather mittens keep you warm while skiing. And when you want to move your fine hands on the snow, such as opening and closing the shell zipper, changing goggle lenses, fiddling with your smartphone, etc., open the zipper and use the 5-finger inner. My hands stay warm because my fingers are not exposed to the outside temperature, what a blessing! The '23-24 season is a reservation sale, and it is an item that is attracting a lot of attention now.

Handling gloves

If you get your favorite glove, you want to use it for a long time. For that reason, let me tell you what I want to be careful about when handling gloves.

drying

If the glove gets wet, it will naturally dry, but it is important not to dry it extremely after getting wet. For example, placing it in front of the stove in the drying room of the inn, or hanging it directly above the stove in the rest house during breaks in the mountains, is actually not desirable. This is because the material is damaged by the rapid application of heat. Ideally, dry at room temperature. It is not unreasonable to think, "Oh! Then it won't dry overnight." Why don't you keep another pair just for that?

filling with oil

Leather gloves should be oiled before use.

This is because, just like human skin, when it dries out, it becomes rough and easily damaged. How often should I apply oil? It depends on the situation, but if you ski 4 or 5 times, it will be one time. glove repair

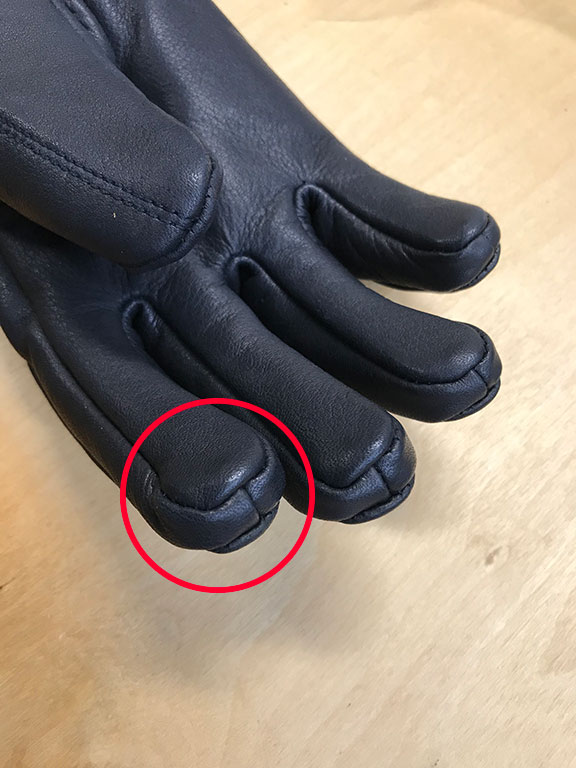

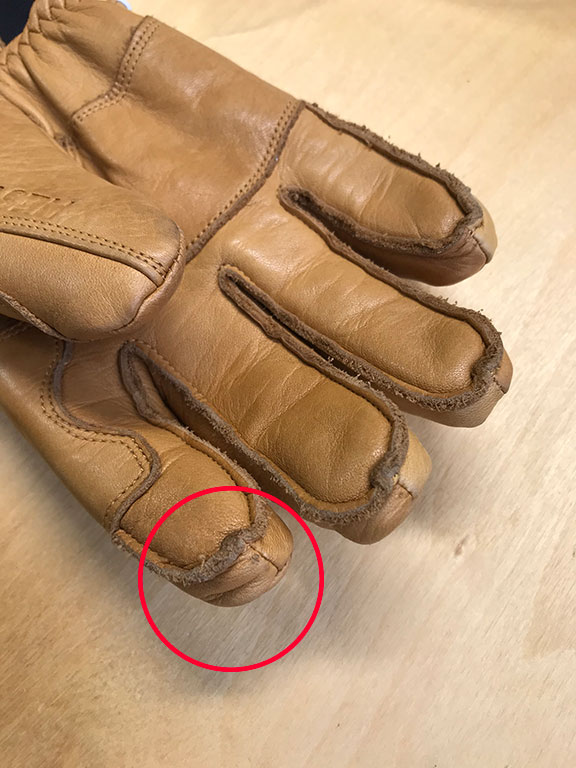

I often see people putting packing tape or duct tape on their gloves that have been rubbed, cut, punctured, or damaged, but I don't recommend it. This is because if you try to repair it properly, the needle will not go through because of the sticky glue of the tape. If you want to have it repaired, take it to a dealer from the beginning. Some manufacturers offer free repairs for one year after purchase, so be sure to check when purchasing.

<Glove repair example>

At the end

Gloves essential for enjoying the snowy mountains. In fact, after going through such an elaborate process, it was made with the ingenuity and commitment of the creator. We hope that you will reconsider your gloves, feel attached to the gloves you have used so far, and find your next partner.

Interview cooperation / Fullmarks Matsuoka Glove Co., Ltd.

Supervision: Yoshio Amano (Fullmarks / HESTRA)