Unlike competition models and general carving skis, freeski models come in a wide variety of shapes and thicknesses. You can enjoy not only compacted snow slopes at ski resorts, but also any slopes, including backcountry skiing. Based on that, I would like to know what the freeski model is from the basics and know the basic knowledge of board selection.

*The basic knowledge of ski structure and materials was supervised by Mr. Masayuki Akiba of Vectorglide, a rider and ski developer.

*Ski specifications: D (dimension = sidecut), L (length = length), R (turning radius)

POINT 1 Character with different waist width

The biggest point that distinguishes a freeskier's character is the width of the waist.

The thicker it is, the more buoyant it is, and the thinner it is, the faster the edge switching. In other words, the wider the waist width, the better it is for powder, and the narrower it is, the better the turn performance is. After that, where to balance buoyancy and turn performance. I would also like to add that each brand has added ingenuity to its outline and structure in order to make up for the disadvantages of each.

[Waist>90mm]

It is easy to transmit the power of the legs directly to the edge, and the carving performance in the pack burn is high. In addition, the overall thin volume is ideal for lightweight tour models.

[Waist = 90-100mm]

This is the waist width that is common in park models. It is easy to edge even on a hard barn, and the outline (waist) that is not too thin makes it easy to jump and grab.

[Waist = 100 to 110 mm]

The most all-around waist width that allows you to enjoy carving on compacted snow and exert the necessary buoyancy in powder. This size band is recommended if it becomes one season.

[Waist = 110-120mm]

Priority skis for enjoying powder. However, at the same time, it is a choice that does not want to sacrifice edge control in hard burn.

[Waist = 120mm ~]

Deep powder model with an extremely thick outline. It can also be turned on compacted snow, but it is more realistic to position it as a second model for deep snow.

POINT 2 <BOTTOM DESIGN> camber and rocker

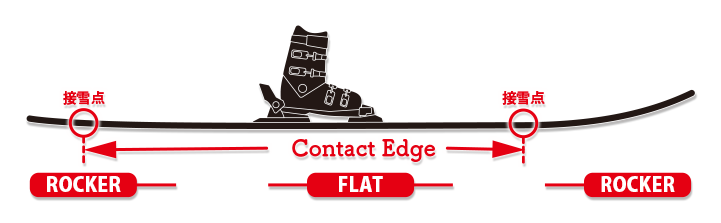

The difference in bottom design has a great influence on the operability and ride quality of skis. The basic principle is that camber makes it easier to switch turns, nose rocker promotes buoyancy and easy turn introduction, and tail rocker makes it easier to slide the tail. There are several combinations of these, and they are adopted according to the use of the ski.

[Camber model]

Classic bottom design with no rocker. Its long contact edges and camber give it agility and stability in turns, but powder requires a certain amount of skill.

[Nose rocker + camber model]

Bottom design adopted by most directional models. The nose rocker promotes buoyancy in powder, and the slightly straight tail creates a sense of stability in the latter half of the turn.

[Nose rocker + camber + tail rocker model] Since

the effective edge is short compared to the overall length, there is a high degree of freedom in riding, and the tail rocker works to slide and glide as desired. A lot of fat freestyle models.

[Full rocker model]

A full rocker that draws a smooth arc over the entire bottom. Sliding operation is easy because the foot is almost flat. You can enjoy free riding on banks, natural terrain, and deep snow.

POINT 3 DIRECTIONAL AND FREESTYLE

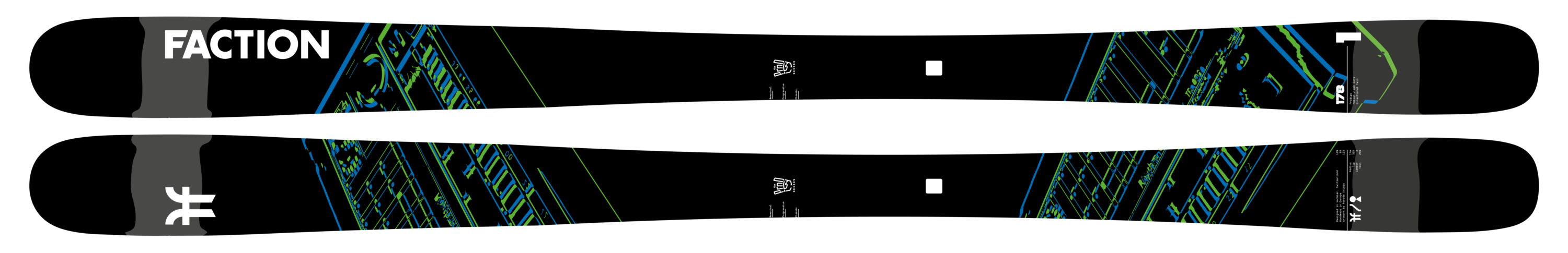

There are two main types of freeski model outlines: directional and freestyle.

"Directional" comes from "Direction", which means direction or direction, and it is designed assuming sliding forward. If skiers before the advent of twin-tip skis read it, they would probably think, "What's the point!?" Excellent turn and high-speed stability, you can enjoy stable high-speed turns even on hard burns.

The "Freestyle" is a twin-tip or twin-rocker model with a cambered tail. Not only can you turn, but you can also fly, rub, slide, and switch to land. The binding mounting position is set near the center of the ski, providing excellent swing balance, and excellent operability and stability in jumps, glides, and switch runs.

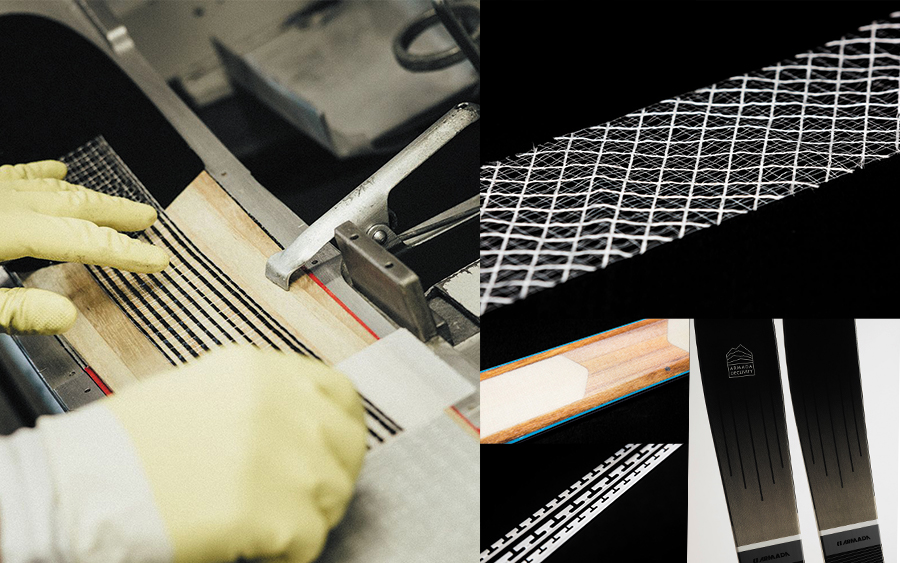

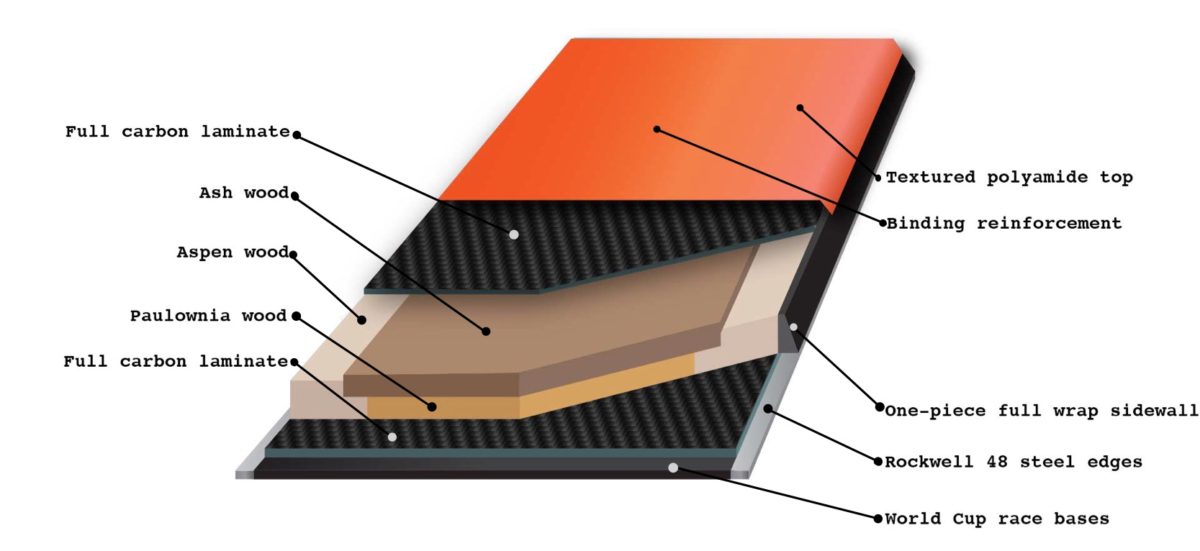

POINT 4 Basic structure

The core material of wood is reinforced with glass fiber, resin, metal material, etc., the edge and base material are layered on the running surface, and the top sheet with graphics is placed on top. This is the basic ski structure. Each part is applied with adhesive and pasted together, and then pressed with a press machine. The options for the types, combinations, and shapes of core materials and reinforcing materials are limitless, and this gives rise to brand individuality and differences in model performance.

When you pick up the ski and push in the center, it bends in a smooth radius, and when you release it, it returns to its original shape. This property, which is important for skiing, is mainly due to the function of the core material. The role of the reinforcing material is to compensate for the strength of the long, thin, and easily broken core material, while also balancing the elements that affect the performance and ride quality of the ski, such as tension, stickiness, resilience, and vibration absorption. Focusing on this core material and reinforcing material, strictly speaking, including the top sheet, sidewalls, base material and edge material, what kind of materials are combined and how? This is modern ski technology.

POINT 5 <CONSTRUCTION> Side structure

When it comes to ski construction, we often hear about whether it's a sandwich or a cap.

Or a semi-cap structure that mixes both. These differences did not have much effect on ski performance and ride quality. The main reason for the different structure of the sides is due to manufacturing reasons. Speaking roughly, the cap structure is suitable for mass production, and the sandwich structure, which requires the labor and skill of craftsmen, is not suitable for mass production. Recently, however, there are signs that this structure is changing. The 3D-shaped structure that we have seen more and more recently is exactly the forerunner of this. Compared to the sandwich structure, the semi-cap and cap shapes have a higher degree of freedom and have the advantage of being lighter, so there are quite a few brands adopting them.

POINT 5 Materials

[Core material (core material)]

Except for junior skis and entry-level models, wood is the mainstream material for the core material of skis. Nothing beats a wood core to provide the supple resilience and smooth deflection that skis need. Naturally, the type, part, and quality of the wood determine the specifications of the ski. However, the hardness and lightness of the wood are not directly reflected in the ski, and it depends on how the layers are combined. Most wood cores are made of laminated lumber rather than veneer. This is because the flexibility and strength are adjusted by combining different materials. There are also examples of inserting advanced materials such as carbon as stringers.

[Reinforcing Material]

Glass fiber is the most commonly used reinforcing material for wood cores. It is a flexible reinforcing material that is easy to process. Carbon fiber is a lightweight and resilient material. Titanal, which has excellent vibration absorption, is an alloy of titanium and aluminum. Each company is currently concentrating their technological capabilities on how to make the most of materials that have negative aspects depending on how they are used.

Supervision = Masayuki Akiba (VETCTOR GLIDE Producer)

Text/Chikara Terakura