Well, suddenly, do you know Jupiter X, which is attracting attention in the industry this season?

It's not that of Kaori Hirahara.

It's not a FUTU◯E that can apply WAX beautifully.

fully automatic tune-up machine developed by Winter Steiger in Austria .

Jupiter X is

●Fully automatic border cutting

●Cleanup

of the running

●Cornering of the side and base edges of the top, center and tail

structures

●Base edge polishing mirror finish It's a new machine.

What is the greatness of Jupiter X?

Up until now, the image of tune-up was that of a delicate craftsman's work that could only be done by hand, but the Jupiter X can process up to 70 pairs of skis in an hour, as long as the settings are loaded into the machine. .

In the case of individual bringing in, depending on the condition of the plate and menu, it can be delivered on the same day. In addition, the biggest advantage of this machine is that you can specify the cornering of the edge and the depth and fineness of the structure, so you can tune up almost freely.

This machine is located at the “Zebra Tune-up Factory (hereafter, Zebra)” in Creb Sports in Yuzawa Town, Niigata Prefecture.

Originally, Zebra, which has a thriving rental business, introduced it to tune up the more than 30,000 rental skis and snowboards, but it also has great benefits for us general users. For example, if you come to Yuzawa-machi in winter and order at the right time, you can quickly tune up and go skiing.

And even more surprising is that there is only one Jupiter X in the world . There are six "Jupiter" machines in the world that only perform edge cornering and running surface polishing, but Zebra is the only machine that integrates all sections and has the "X" title . .

If we can experience the state-of-the-art machine that is causing a stir in the industry, there is no reason not to cover it.

The editorial department went to experience how much the ability is.

Diagnose by actually taking

Zebra

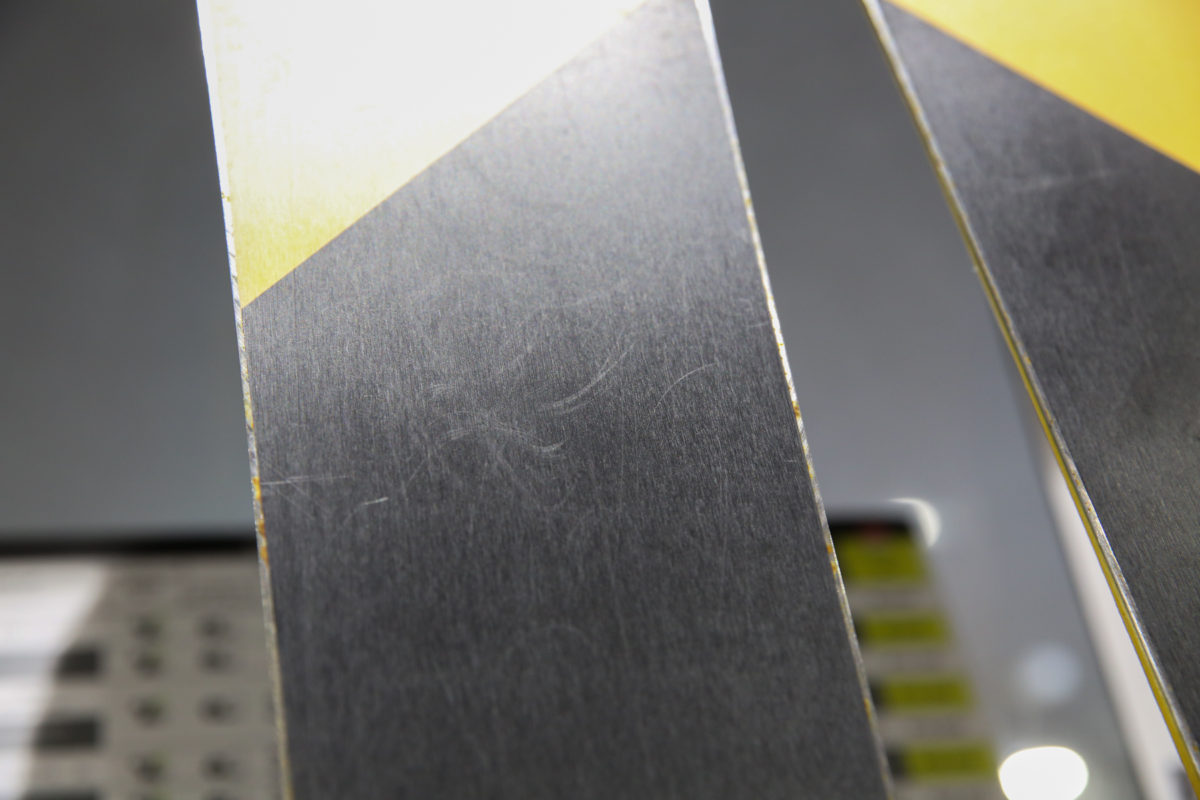

to ask for an interview, and they readily agreed . Skis that have been used for two seasons and have never been tuned up.

When I took it in and looked at the soles of my skis again, I was kind of sorry or embarrassed. do not have. There are large and small scratches, and the edges are also rusted. Or rather, since it enters the rail, there are many intentional scratches on my feet.

"Will this make me beautiful?"

I asked timidly.

“A certain amount of scars will disappear cleanly!”

Mr. Suda, who is in charge of Jupiter, gave me a refreshing and immediate answer.

It was said that the scratches on the sole when entering the rail would be clean, but a large scratch like stepping on a stone might remain. The point is that the sole is polished and the damaged surface is polished, so if you polish it too much, it will affect the durability of the board itself. The sole became beautiful, but it became thin and the ski broke.

In addition, it was said that the edge part of the foot that was rounded due to the influence of the rail may not be perfectly cornered. Again, the edge was polished too much, and the edge itself disappeared.

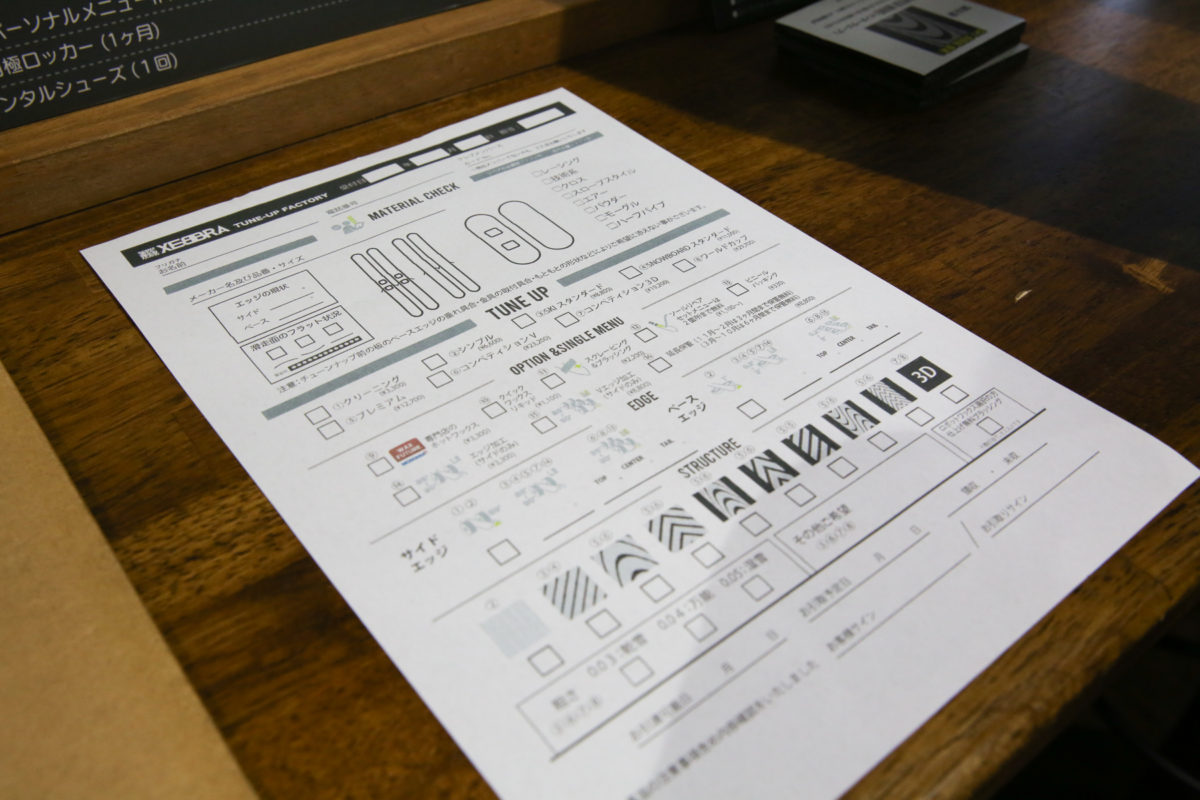

So, to what extent and what kind of tune-up is the best for the board, we carefully check the material before putting it in the Jupiter X.

At that time, what kind of place and how do you ski? It is said that the setting is proposed by taking into account the individual's preference. This diagnosis is very important to make it an ideal board.

As a result of this discussion,

・First, flatten the sole.

・Set the side edge to 88.0 degrees and the base edge to 1.5 degrees

・Insert structure

Roughly speaking, I decided to perform maintenance with this policy. This plan is 12,700 yen including flat polishing of the sole, polishing and cornering of the edge, and adding the structure.

The skis I brought were reborn...

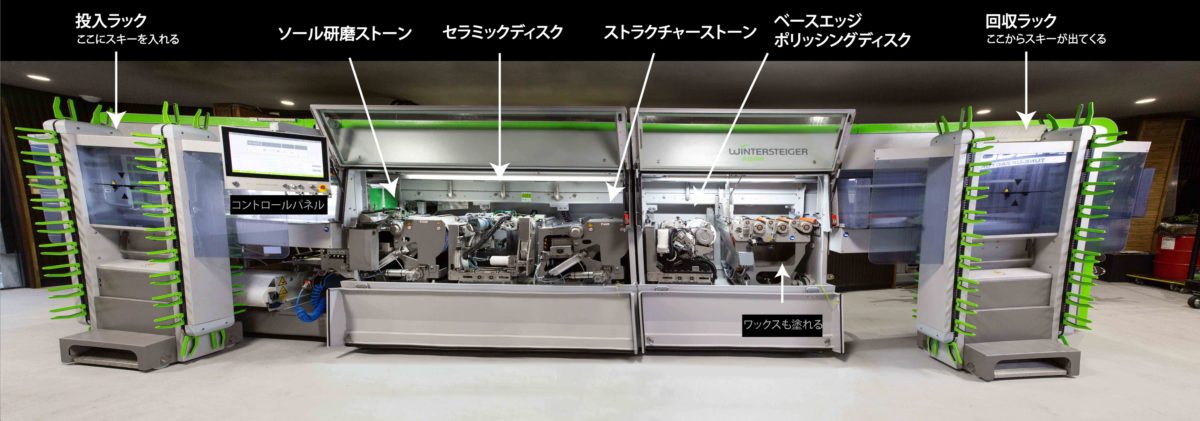

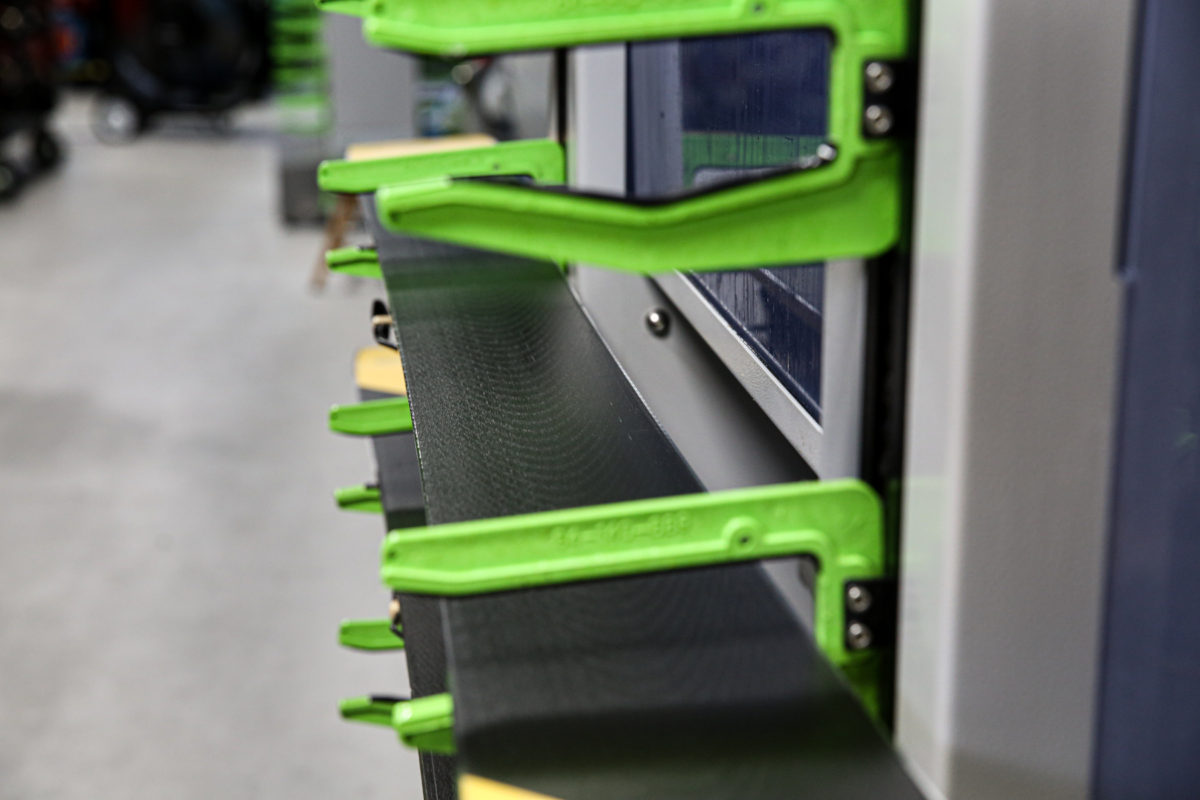

Jupiter has such a machine installed in the body with a total length of 8.35m.

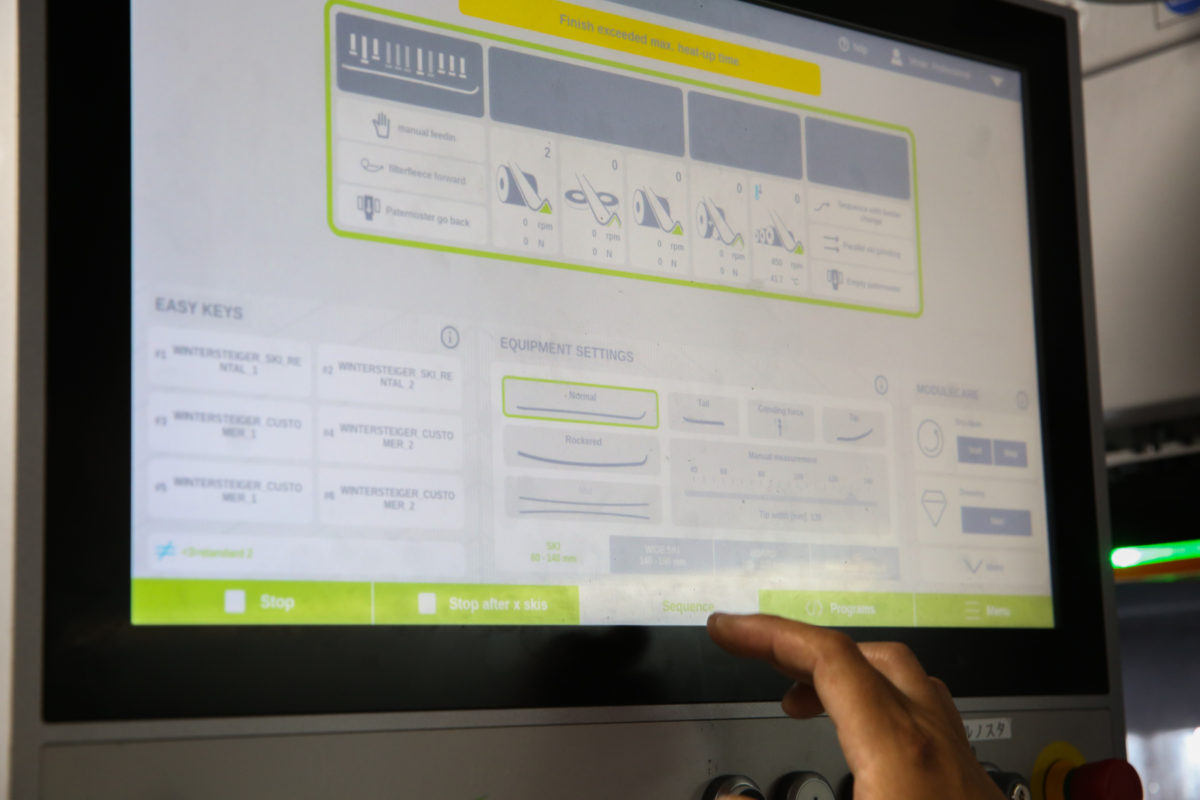

First, set what kind of tune-up you want to do from the control panel on the left. The shape of the board, the speed at which it is sent, and the rotation speed of the stone that grinds the running surface and edge. Also, by setting the sequence, you can make detailed settings such as polishing not only from the direction of movement, but also from the back. The advantage of Jupiter X is not only speed, but also accuracy. You can insert the board straight and tune up with constant pressure and speed.

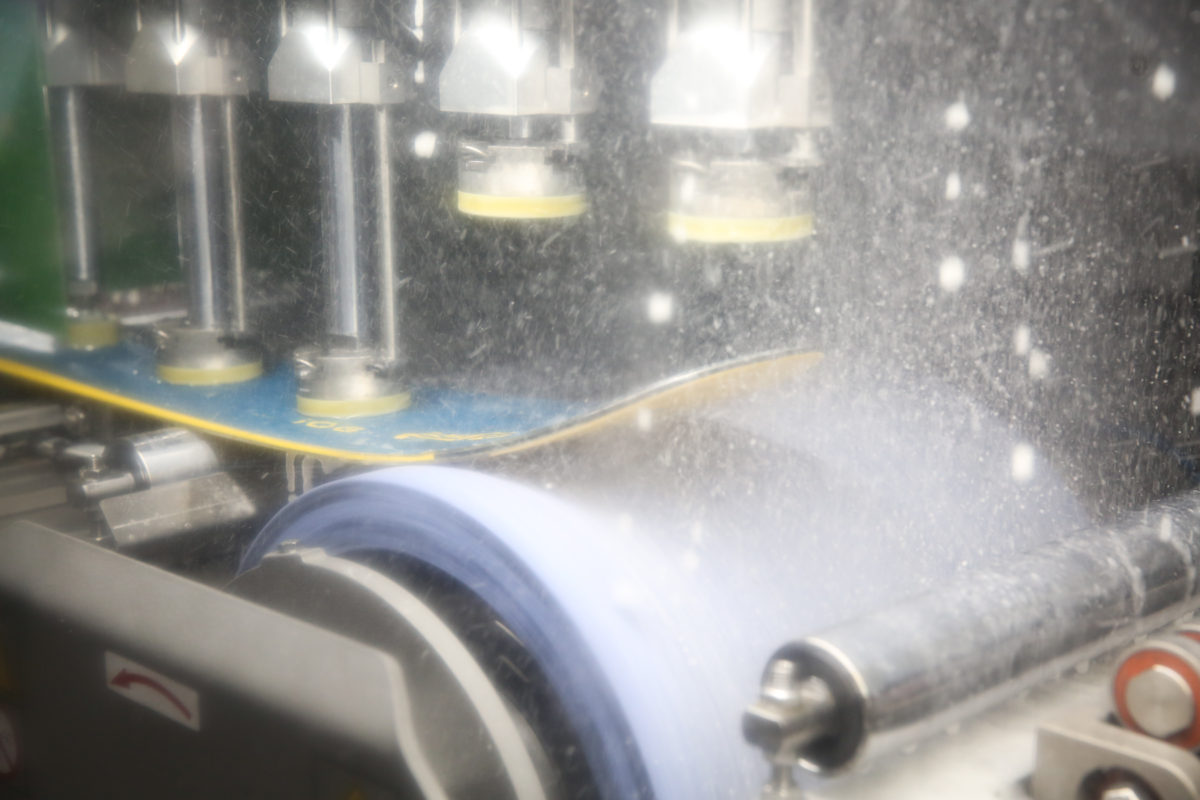

First, polish only the sole once and see how it goes.

Jupiter X can do all the processes at once, but since the way of tune-up is different for each general user's board, we work while checking the finish each time regarding sole polishing and edge cornering.

! ? The work was over in no time, and even if I just polished the sole once, it was finished very beautifully with quite a few fine scratches removed.

Next, sharpen the edges. Set so that the whole is at an angle of 1.5 degrees and put it on the machine. I'm wondering what will happen to the rust on the edge that was here and there.

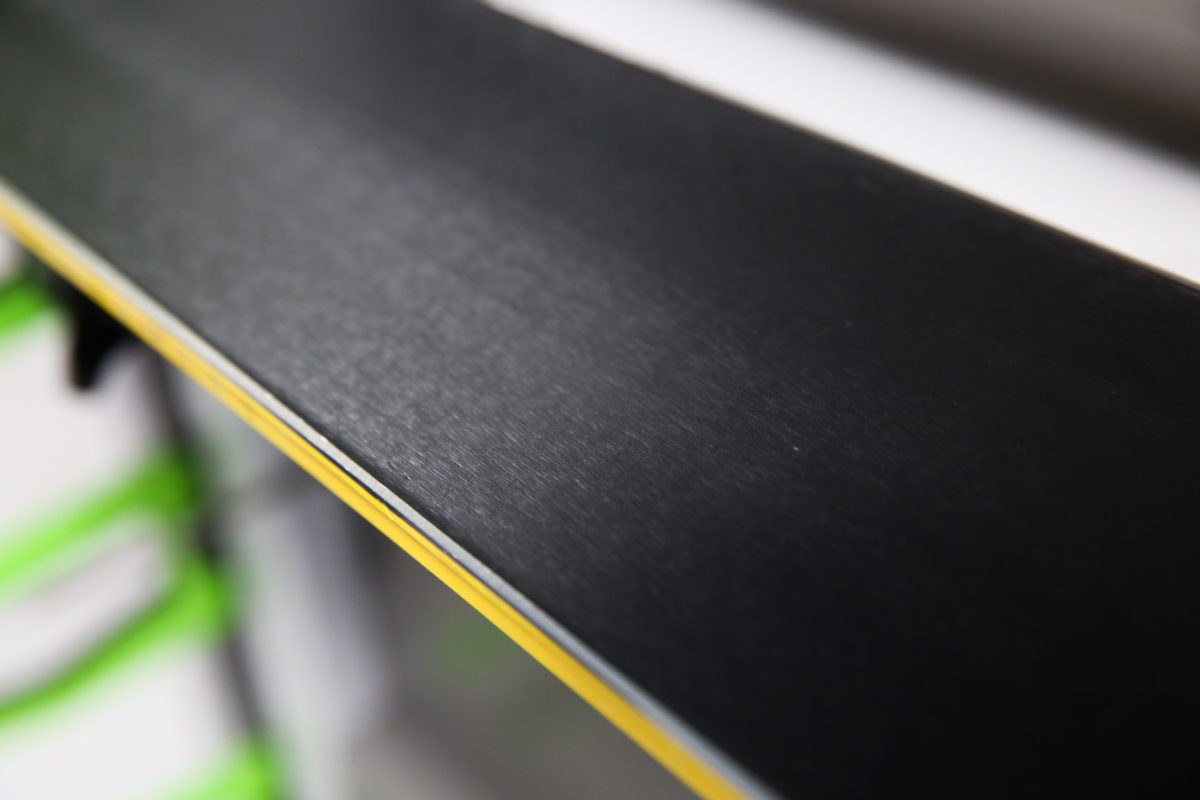

And what came out is ...

A ski with a beautiful edge has appeared. "Is this really my board?"

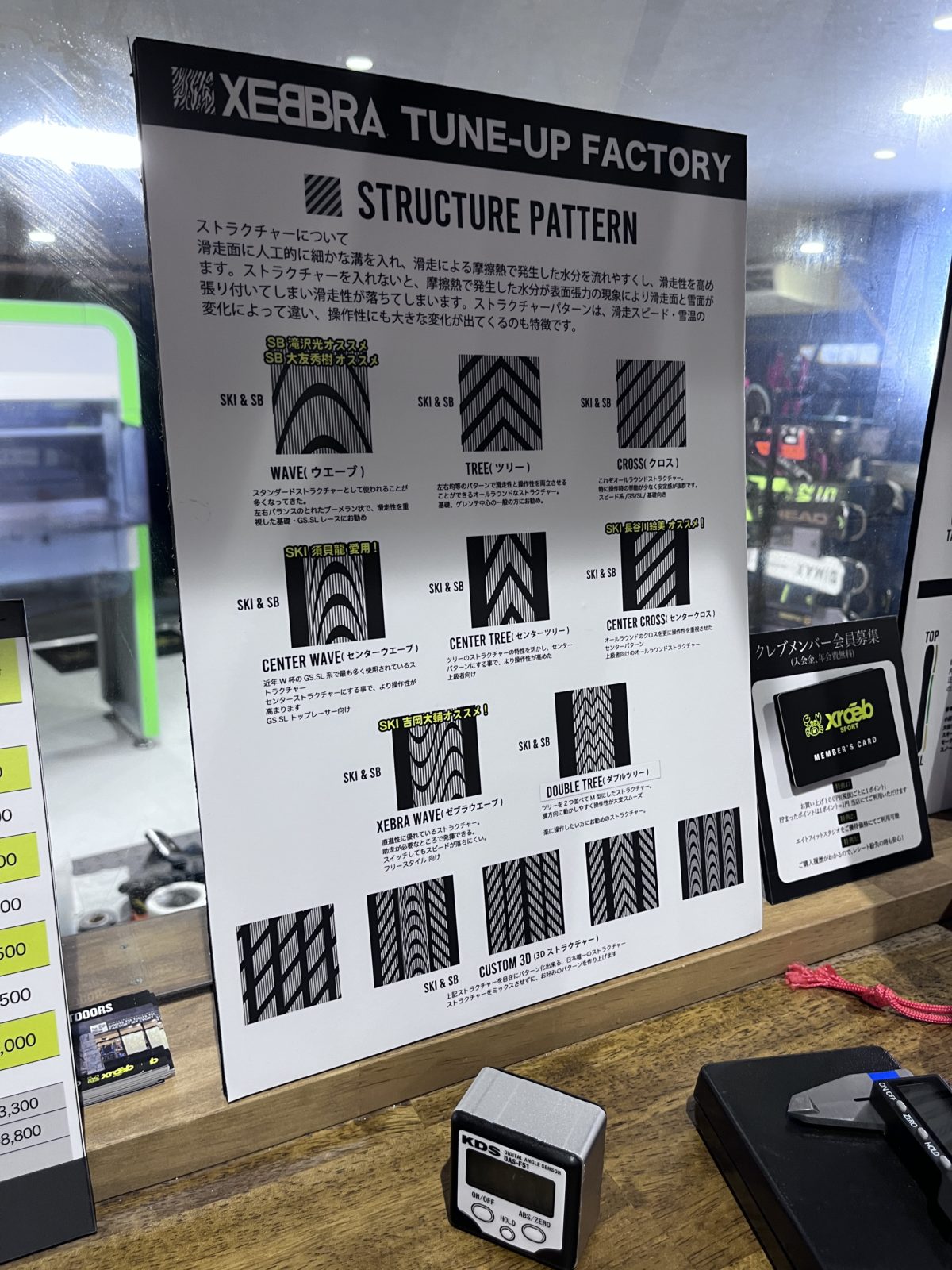

Then add structure. This structure is the work of artificially making fine grooves in the sole. This facilitates the flow of moisture generated by the frictional heat of gliding. Without a structure, water will accumulate between the sole and the snow surface like surface tension, and the skiability will be reduced.

The structure is so important that each ski manufacturer has a secret structure pattern that is directly linked to ski performance.

The strength of Jupiter is that you can put this structure almost freely by setting it. Furthermore, the function that will be upgraded in the future is "3D structure". Not only can any pattern of structure be put in, but the depth can also be adjusted for each part, which normally can only be finished at a fixed depth.

This time, I decided to use the CENTER WAVE pattern recommended by Ryo Sugai, who competed in the Beijing Olympics ski cross. It is an epoch-making structure that combines operability and sliding performance by adding a groove in the center that allows water to flow easily and not inserting a structure on both sides near the edge.

Load the structure settings in the control panel and set the depth. You can choose between shallow, medium and deep. Medium depth this time. Here's what came out.

It's a little hard to see in the photo, but you can clearly see the pattern with the naked eye.

Finally, polish the base edge with a finishing disc.

This is the work of removing some scratches on the base edge from the stone disc and finishing it to a mirror finish. I would like you to see what this looks like in the video.

The traces of polishing, which had been visible until now, were completely gone and the surface became smooth.

The actually finished board has almost no scratches on the running surface, and the structure is also excellent. The rust on the edge that was protruding here and there disappeared completely, and the polishing disc removed even the slightest scratches. There is a roundness in the part that touched the rail at the foot, but it can not be helped because the edge itself will be lost if it is cut further.

It took about an hour from the diagnosis to the end of the work. Since I was interviewing, the work itself will probably end a little earlier. Depending on the board, if the sole or edge is damaged, more work will be required to polish it, but the board I brought this time was spent in the trees and parks without worrying about anything during the season. I think he has a lot of scars.

This time it was a plan of 12700 yen to sharpen the edge, polish the sole and add a structure, but personally I am very satisfied because my favorite board has been reborn and returned to me.

For the time being, I am looking forward to skating on this board, which has a perfect structure, this season.

Jupiter X can also be viewed through the glass from inside the KLEVB store. If you are interested, please visit the Zebra Tune-Up Factory inside the KLEV store when you visit Yuzawa this winter.

Also, if you want to check the operation of Jupiter in the video, please visit the manufacturer's YouTube

Sports

〒949-6102

39-8 Kandatsu, Yuzawa-cho, Minamiuonuma-gun, Niigata Prefecture

025-788-1788

Interviewed and written by Daigo Onozuka