Ski boots are, in some ways, the most important item connecting your body to your skis. Currently, the freeride boot category includes two-piece and three-piece boots with different shell structures, each with or without hiking functionality, different sole standards, and compatibility with bindings. Let's take a look at the reasons and meanings behind these diverse designs. This is a refresher on the basics of freeride ski boots

POINT 1 | What are freeride boots?

Here, we will collectively refer to freestyle and freeriding models as "freeride boots." It would seem more appropriate to call them "all-mountain boots," but some brands refer to their resort boots as "all-mountain," so we want to distinguish them from these

The overall trend is to combine gliding performance with light weight (climbing ability). Ski brand boots maintain their original gliding performance while reducing the stress of hiking up by using lighter materials and parts.

Meanwhile, the so-called touring boots of mountain boot brands have evolved in terms of shell materials and structure, and there are an increasing number of models that are not only light and easy to walk in but also provide a natural gliding performance. Furthermore, even boots that are only for gliding and do not have hiking functions are beginning to take advantage of the benefits of light weight.

POINT 2 | 2-piece and 3-piece

Two-piece shell construction:

The lower shell provides power transfer and flex, while the upper maintains the forward lean angle of the leg and supports accurate positioning.

The two-piece shell provides excellent direct power transfer and is ideal for turn-focused riding. If you want to enjoy turn control that traces the intended line and high-speed skiing, there is no better ski boot.

XT3 TOUR LIGHT MV 130

HAWX PRIME XTD 130 GW

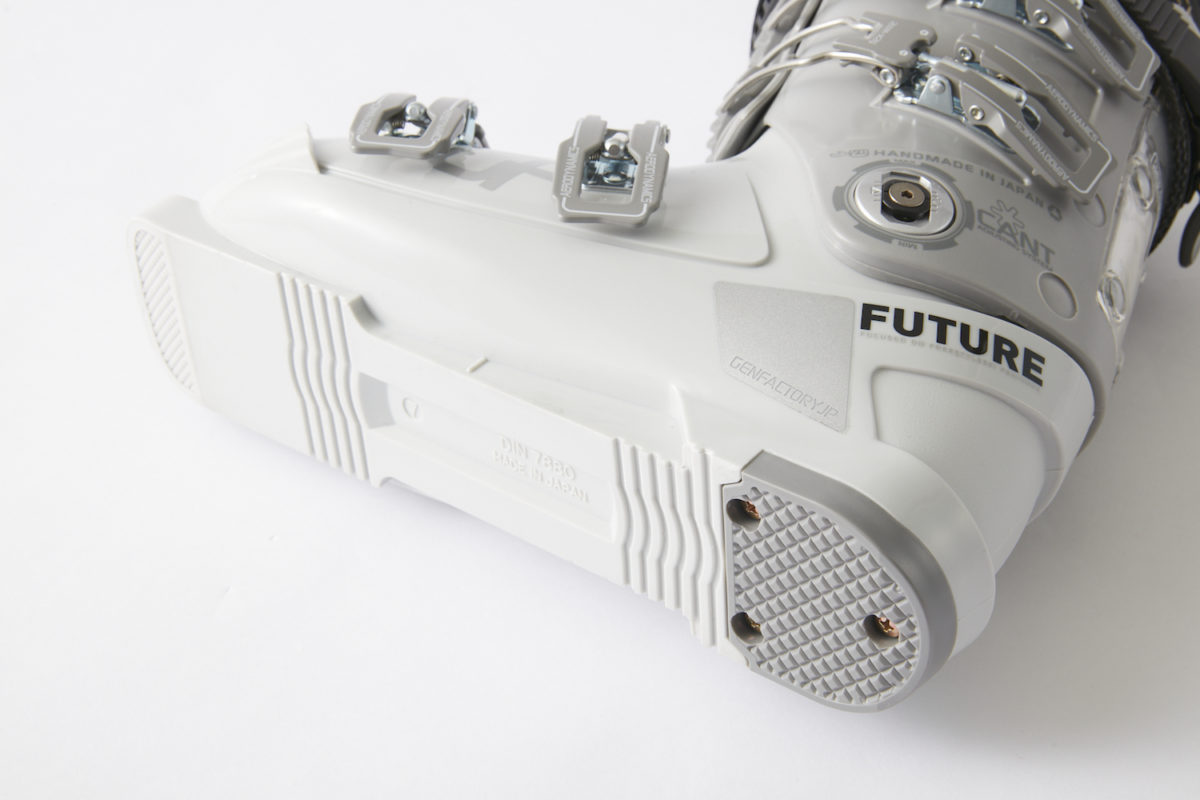

FUTURE

[3-piece shell construction]

The rigid lower shell transmits power, while the independent tongue controls flex. The cuff can move back and forth effortlessly. The

independent tongue makes it easy to set the flex of the 3-piece shell, making it a perennial favorite among skiers who prioritize ankle movement. The construction also allows for a large range of cuff movement, which is why most touring boots use this 3-piece construction. The hinge connecting the lower shell and cuff is located close to the actual ankle, which is another hidden factor that prevents the ankle from losing its flexibility.

DIVERGE SC

MAESTRALE RS

CABRIO LV 130

POINT 3 | Shell material

The shells of most ski boots are made of polyurethane (PU), which provides the stiffness needed to transmit power and the supple flex (flexibility and resilience) needed for turning

The shells of lightweight touring boots are often made from polyamide resins, such as Pebax and Griamide (also known as Grilamid). Because they are harder and lighter than polyurethane, they allow for a thinner shell and a lighter overall weight. They are also valued for their ability to maintain their hardness even at low temperatures

POINT 4 | Last width

A "last" refers to the shoe shape. The narrower the last width, the stronger the hold, and the wider the last width, the more comfortable it is. Race boots are generally in the 90mm range, and freeride boots are generally in the 100mm range. If you are prioritizing warmth in the backcountry, for example, a wider last width is recommended

POINT 5 | Differences in buckles depending on shell structure

The number and position of buckles is also considered very differently between two-piece and three-piece shells. Two-piece boots, which require a firm hold all the way to the toes, often have four buckles that tighten from the toes to the ankle. On the other hand, three-piece boots prioritize hold from the heel to the arch area, with a placement that leaves more room in the toes. This has the advantage of preventing pain caused by the toes getting jammed together when landing from a jump, and reducing the risk of your toes getting too cold in low temperatures

POINT 6 | Three types of sole shapes

There are three main types of soles. There are two international standards: the alpine boot standard (ISO 5355) and the touring boot standard (ISO 9523). Additionally, the GripWalk sole, which is a touring boot standard but compatible with safety bindings, is becoming increasingly popular. With the exception of GripWalk, the welt height and sole shape are different and incompatible with bindings other than those that comply with each standard. Even if it were possible to fit it, the binding's inherent holding and release functions would not function properly, making it extremely risky and best avoided.

For information on binding compatibility, please see here.

[Alpine standard sole (ISO 5355)]

The flat sole of conventional ski boots. Generally only compatible with alpine standard bindings.

Touring standard (ISO 9523):

The sole is equipped with rubber blocks and rocker for easy walking. The toe edge is higher than the alpine standard sole, so it is not compatible with alpine bindings.

Gripwalk sole:

A resin plate compatible with the binding's sliding AFD is placed inside a rubber block that makes walking easy. Most of these soles comply with the touring boot standard (ISO 9523).

POINT 7 | Compatibility with tech bindings

Tech inserts in the toe and heel allow for tech bindings, which many touring boots now offer, including those with GripWalk soles

[Toe]

The toe side has a system where the tech insert on the welt is clamped with a pin to secure it in place.

[Heel]

Hooks and holds the two bars on the heel piece of the tech binding.

POINT 8 | Inner boots

Many boots now use heat-moldable inner liner (liner). Not only does this dramatically improve the fit, but it also fills the gap between the inner liner and the shell, preventing slippage inside the shell and providing a solid, integrated fit from bare feet to the shell. Another major feature is its high thermal insulation. Furthermore, more and more models are available with heat-moldable shells, so be sure to check them out

[Wrap type]

The shape that wraps around the ankle securely provides a comfortable fit that is held in place to a certain extent even without fastening the buckle.

[Tongue type]

The traditional inner with an independent tongue fits comfortably and follows the movement of your ankle when turning.

[Insoles]

Three-dimensional insoles that fit your heels well prevent the soles of your feet from slipping, effectively improving performance. Heat-molded insoles are also available commercially and are extremely effective with little investment.

POINT 9 | Walk mode function

Nowadays, many freeride models, not just touring boots, are equipped with a walk mode. When you switch modes, the lock is released and the cuff can move back and forth. While you may not feel much benefit when climbing steep or short climbs, when walking on gentle slopes or flat ground, a wider range of motion in the cuff allows you to take longer strides, resulting in faster and easier movement

In addition to backcountry scenes, there are many other places where this advantage can be utilized, such as when moving around large parking lots at ski resorts, waiting in line for a ropeway, or riding while standing

[Mode change lever]

The lever located at the back of the cuff switches between glide mode and hike mode.

Supervised by: Hiroyuki Tsuji (Gen Factory), Ryusuke Miura (MDV Sports Japan), Tomoya Takahashi (Dynafit)

Text: Chikara Terakura