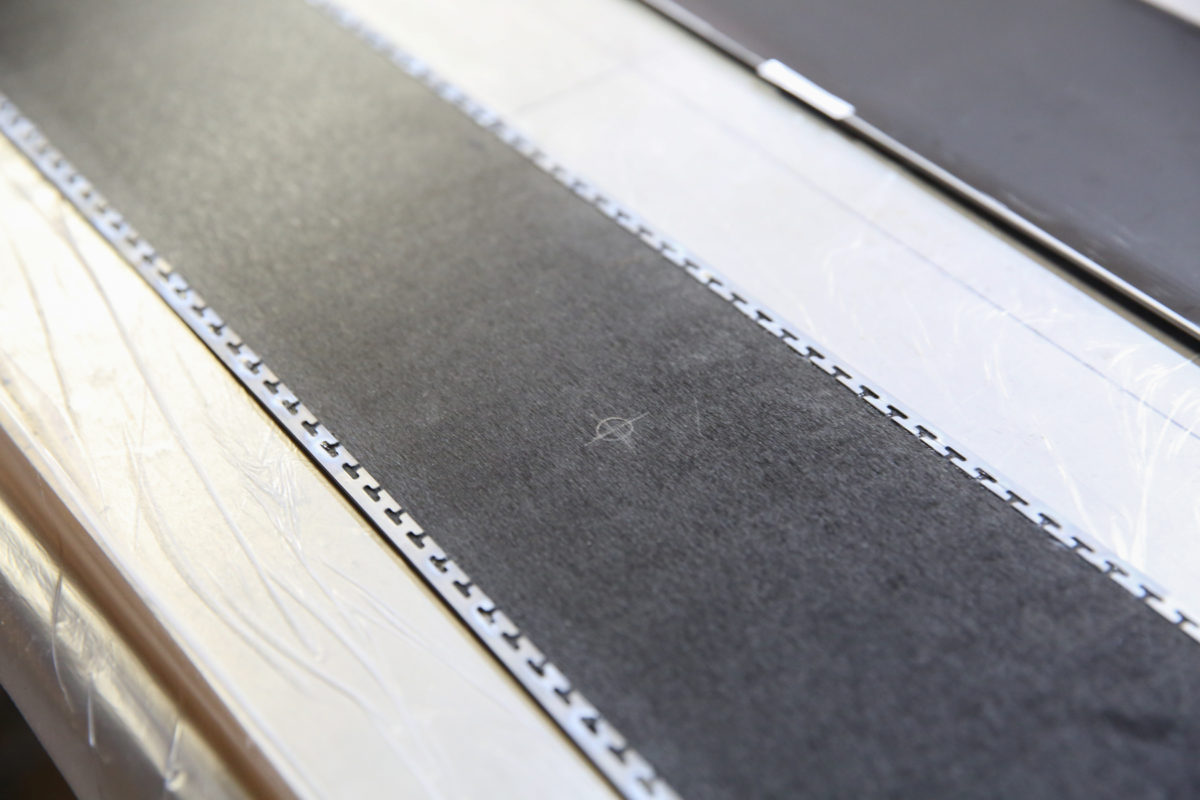

Assembling the materials

From here, everything comes together and we approach the highlight of ski making:

fitting the bent edge onto the sole and gluing it together.

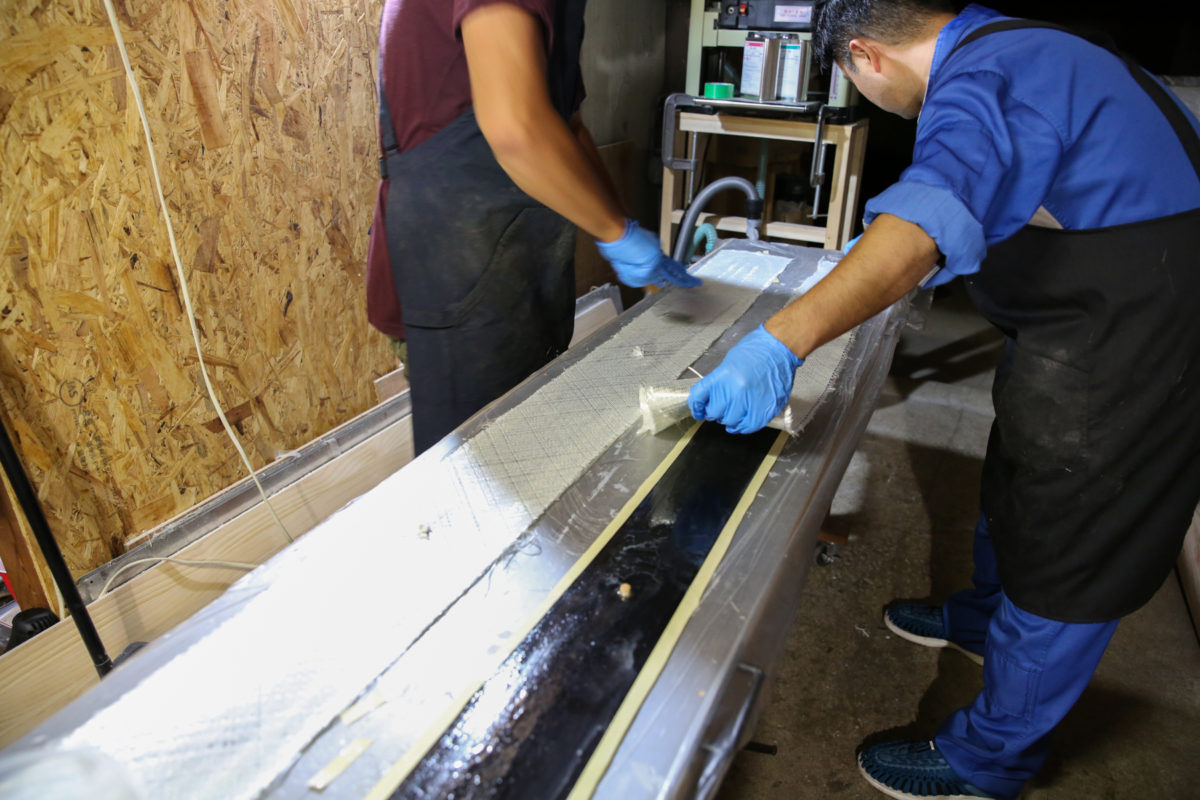

Resin is applied on top of that and fiberglass is then layered on top. By the way, resin is "epoxy resin." It is not familiar to men, but it is often used in women's nail art. The resin used this time is a two-part resin made by mixing a base resin and a hardener. This will bond and harden over time

Once the resin is evenly applied, a layer of core material is placed on top. Then, more resin is applied. Then, another layer of fiberglass is placed on top of that and more resin is applied. This process is called layering

While layering this fiberglass, reinforcing materials such as carbon and titanal can be layered.

The advantage of the sandwich structure is that even if reinforcing materials are added and the ski becomes thicker, it can still be pressed. This means that skis can be packed with various materials.

In making this ski, I wanted to experience the natural flexibility and hardness of wood as much as possible, so I used only fiberglass as a reinforcing agent. Up until now, I've only ridden skis that incorporate advanced materials, so I wanted to try a ski that was closer to the natural feel of wood. Incidentally, fiberglass acts like a spring, giving the ski just the right amount of rebound. The brand basically sandwiches two pieces of fiberglass above and below the core material, but depending on your preference, you can even omit it

After laying down the second layer of fiberglass, place the graphic you just printed on top and then lay down the top sheet on top of that

The top sheet is primarily for protection and does not have any particular functional role in terms of gliding.

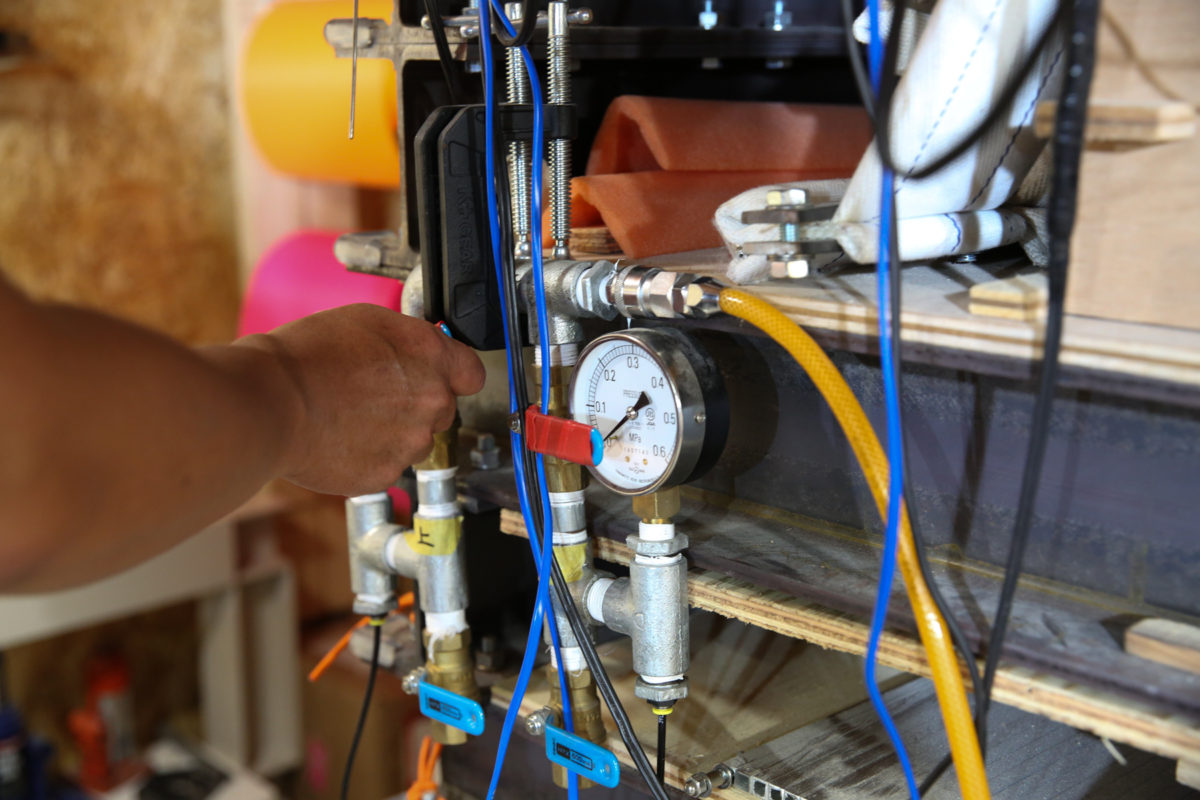

Now that the materials have been layered together, it's time to press them together.

The tire is then placed in a press at a total pressure of 4 atmospheres and heated to 80 degrees Celsius for about an hour. The pressing process bonds all the materials together and shapes the camber and rocker

The one and only ski in the world is finally unveiled

And this is what came out after an hour of cooling

We are finally getting close to the shape of the board. At this point, it is 90% complete. All that remains is to cut it out into the shape of a ski along the edge

This is my board, the only one of its kind in the world. Of course, there is a template, so it can be duplicated. I can make as many boards as I want. Of course, it meets JIS standards, so it is properly recognized as a product

When I actually made it, it was much cooler in person than what I had imagined in my head. The more I looked at it, the cooler it looked. The shape and graphics are so cool that it makes me tremble when I think that it's the only board in the world.

Because I designed it myself, I tend to look at it through dark glasses.

The boards are still soft when they're warm after pressing, so the stiffness will apparently settle down after about a week. Although I made the board thinking that a softer board would be better, when I bent it under my weight, it felt a little too soft. If

it could settle down a bit more and become the softness I like, that would be great.

All that's left now is to actually ride it on the snow and test how it feels. It's

only just September, but I can't wait for winter to arrive. I'll definitely be taking these boards with me when the ski resorts open early in November.

I can't stay happy forever..

Now, there is one concern I noticed after actually making the boards:

the amount of waste.

The photo above shows only a small part of the trash that was generated during the cutting process.

As people who are allowed to venture into nature and enjoy themselves, we cannot accept the idea of leaving a lot of trash behind and then skiing freely in the powder snow with a "Yahoo!"

As you know, burning wood as garbage requires transportation and fuel for combustion, which results in the emission of greenhouse gases. Also, since wood is mixed with fine metals such as fiberglass, it must be treated as industrial waste

Nagai himself

says, "This garbage problem is one of the things that we need to solve in the future."

Voltage Design is currently working on turning the wood scraps that are produced during board production into smartphone cases and accessories, but this is not enough. They are constantly searching for more effective, radical solutions

We too have an obligation to know. To produce is to consume at the same time. I don't intend to deny consumption, but behind our activities, what do we gain in return, and what are we paying for? Rather than leaving all problem-solving to others, we should think about it ourselves and perhaps even change our behavior by learning more

This time we looked at the behind-the-scenes of ski manufacturing, but if it were ski wear or gloves, different things would probably be consumed

Making your own unique pair of skis is not only the greatest happiness for a skier, but also a valuable experience that allows you to learn about the materials used to make skis, their structure, and the processes that go into making them

Of course, anyone can also create their own unique pair of skis, and even get involved in the on-site work.

If you create a ski yourself, you'll feel a special sense of satisfaction while skiing. You'll likely develop a strong attachment to it and ride it for a long time.

works as a mountain guide in the winter and devotes himself to making skis and snowboards day and night in the summer.

Board development is updated daily, so for more details, check out Nagai's Instagram.

Instagram

. Voltage Design website.

Interview and writing: Daigo Onozuka